The C151 End-of-Life Upgrading Project was a partially-completed train refurbishment and PMSM retractioning project undertaken by SMRT on Kawasaki Heavy Industries C151 trains. The project involved replacing the propulsion system, HVAC and auxiliary power system (APS), train management system, brake control and the compressor on each train.

Slated for upgrading were sixty-six (66) KHI C151 trains were manufactured between 1986-1989 by a Japanese consortium led by Kawasaki Heavy Industries (KHI). They entered service in 1987 on the North South Line (NSL) and East West Line (EWL), making them the first generation of rolling stock on these lines.

The upgrading project was terminated prematurely after LTA decided to procure brand-new R151 trains from Bombardier as replacements for C151 trains. Only six trains were upgraded with PMSM traction motors, and other planned upgrades were not known to have taken place.

Article Layout

- Background & timeline of C151 EOL Upgrade

- PMSM Project Launch

- Prototype train

- Fleet rollout

- Key Specifications & Advantages

- Engineering Work

- Project Termination

- List of upgraded trains

Background & Timeline

In the wake of two major train disruptions in December 2011, a Committee of Inquiry (COI) report mentioned that the failures of multiple train components could be regarded as a sign of ageing assets. It noted that although C151 trains had received interior refurbishments in 2006-2008, there did not appear to be any upgrades in terms of engineering components. It also recommended the installation of a Train Information Management System, which allows train operators to actively monitor the performance of on-board systems (only C751B trains and later had them installed).

In light of these recommendations, SMRT announced in May 2013 that it would replace all important engineering components across all C151 trains by 2019. This would involve the replacement of the propulsion system, heating, ventilation, and air conditioning (HVAC), auxiliary power system (APS), train management system, brake control and the compressor on each train.

As reported by the International Railway Journal, the C151 trains had a design lifespan of 30 years, and SMRT’s own engineering assessments also concluded that the C151’s car body structures were structurally sound for another 30 years. Therefore, comprehensive renewal of these important components would help to extend the service life of C151 trains.

C151 PMSM Upgrade – Project Launch

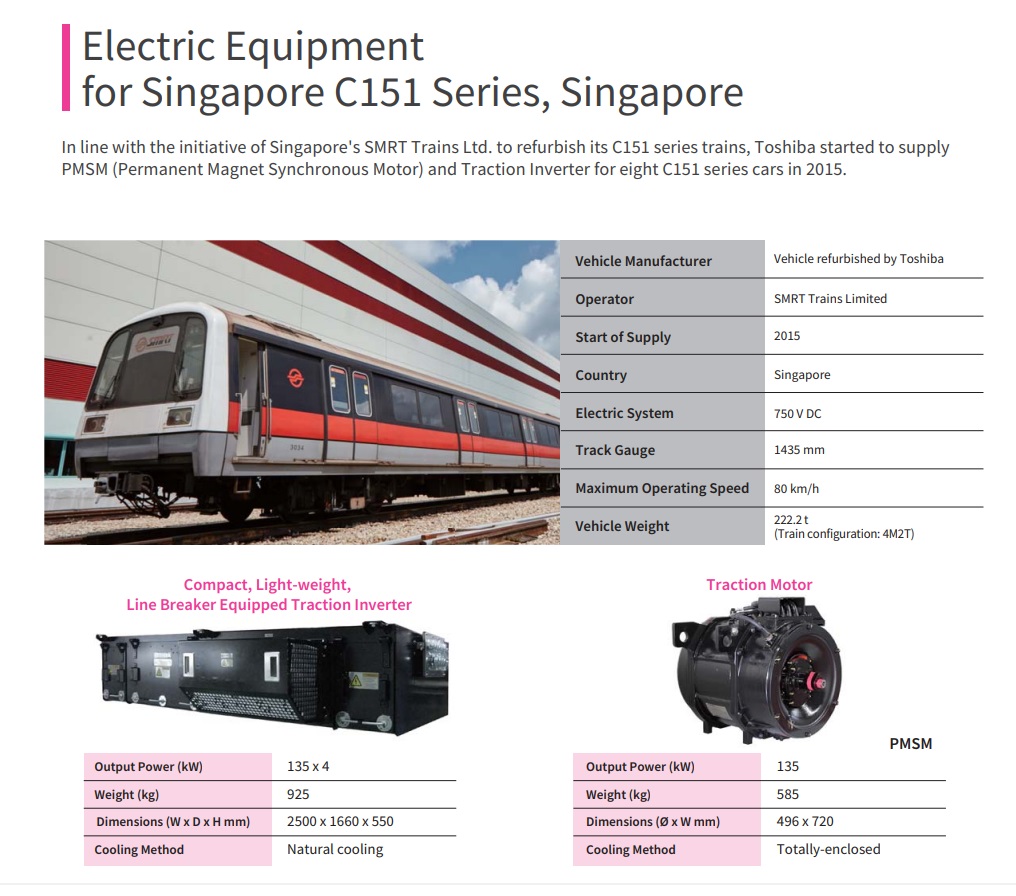

For the retractioning effort, SMRT cited reliability as the key consideration for its operational needs, with energy efficiency, maintainability, life cycle costs and noise levels as secondary factors. It eventually selected Toshiba’s Permanent Magnet Synchronous Motor (PMSM) propulsion system, which met these criteria.

| Old (Mitsubishi Electric) | New (Toshiba) | |

| Traction Control | 4-quadrant/GTO chopper control | IGBT-VVVF |

| Traction Motor | DC shunt-wound motor | Permanent-magnet synchronous motor (PMSM) |

In July 2013, Toshiba was awarded the PMSM retractioning contract for all 66 C151 trains. This is the first deployment of the high-efficiency PMSM outside Japan, and Toshiba intended to use it as a springboard to winning further orders in the global market. It would perform the PMSM upgrade on two prototype trains, and once successful, would then roll out the upgrade to all C151 trains.

Toshiba’s new inverters and peripherals would replace the original Mitsubishi Electric traction system. The company would also collaborate with Japan Transport Engineering Company (J-TREC), a Japanese rail car manufacturer, for the retrofitting process. J-TREC, formerly known as Tokyu Car Corporation, was part of the Kawasaki-led consortium that manufactured C151 trains in the 1980s.

In an effort to build on garnered expertise, Railise Pte Ltd was formed in September 2013 as a 50:50 joint venture between Toshiba and Singapore Rail Engineering. Railise would build on expertise garnered as part of the planned PMSM upgrading of C151 and C651 trains in Singapore, and offer integrated re-tractioning solutions to rail operators worldwide.

Singapore Rail Engineering background (Click to expand)Singapore Rail Engineering (SRE) was incorporated in 2014 under SMRT Corporation, with the intention of growing an indigenous rail engineering capability contributing directly to rail reliability in Singapore. It develops and invests in core engineering expertise, and trains skilled personnel to provide a complete set of engineering services to support and maintain the SMRT metro network, while also making headway in opening up overseas engineering services markets.

The SMRT subsidiary mainly targets rail MRO (Maintenance, Repair, and Overhaul) activities arising from the maintenance cycle of rolling stock, including the midlife upgrading and/or refurbishment of trains that have been in operation for 15 years or more. It also formed joint ventures with Toshiba and Faiveley Transport.

At the time of the C151 refurbishment project’s termination in 2018, SRE was refocused on deepening its capabilities in subway operation and maintenance engineering, in line with new requirements set out by the New Rail Financing Framework.

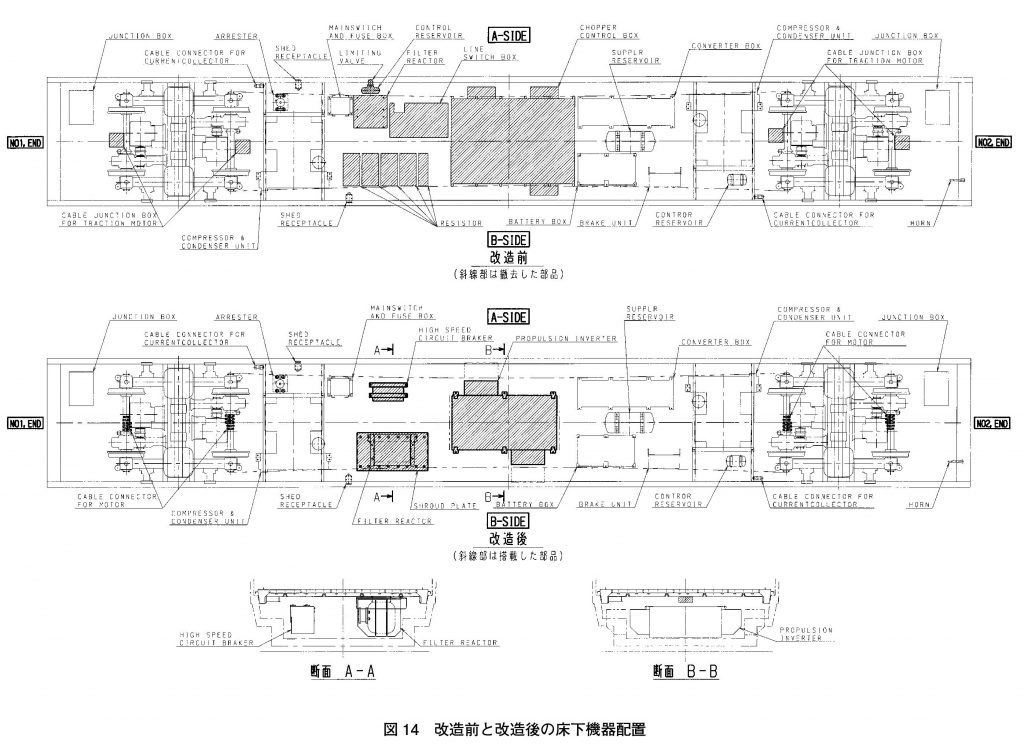

The main equipment supplied consists of a traction inverter, a high-speed circuit breaker, a filter reactor (line reactor), and a PMSM motor. The first train was projected to enter service in 2Q 2015.

Prototype train

Manufacturing and interfacing work was carried out by Toshiba until October 2014, and a final Factory Acceptance Test was carried out at Toshiba’s Fuchu factory with SMRT staff in attendance. After that, the unit was shipped to Singapore and installed in December 2014. Toshiba worked with J-TREC to integrate the PMSM system on these trains.

The retractioning project was first tested on two prototype trains, 055/056 and 131/132. Dynamic testing was carried out on SMRT’s test track between February-April 2015, followed by further compatibility tests with the Siemens automatic train operation system, and main-line running tests in June-July 2015.

The prototype trains were successful in delivering on three key performance indicators (KPI): delivery of at least 30% energy savings compared with the existing system; a noise reduction of at least 12 dB, and the completion of a six-car train recovery during an emergency operations test (i.e. 12-car haul).

Both prototype trains (055/056 and 131/132) entered revenue service from 30 July 2015, initially on the EWL’s Changi Airport Branch, and subsequently appearing on the mainline EWL from end-September.

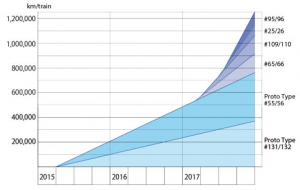

Fleet rollout

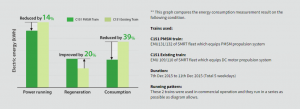

Initial results from the prototype trains were encouraging, with all three key KPIs continually being met, and no in-service failures reported. Energy measurement tests carried out on revenue service trains between 7-11 Dec 2015 reported an energy saving of 38.6%, more than the 32.81% achieved in tests.

Convinced by the system’s performance, SMRT decided in December 2015 to proceed with the retractioning of all 64 remaining trains, with a contract for the remaining work issued the following month.

Key Specifications & Advantages

Energy Efficiency

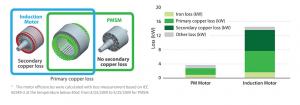

PMSM motors use about 30% less energy than a conventional DC traction-based system. They are also highly efficient, with an efficiency rating of 97%, over DC motors (87-90%) or AC induction motors (91-94%), based on figures from Railise. A large contributor to these efficiency gains is the elimination of secondary copper losses. It also offers higher utilisation of regenerative braking, ideal for metro operations.

According to consumption figures from Toshiba obtained from revenue service trains, the PMSM motors offer a net 39% reduction in energy consumption versus the legacy DC motor and traction gear.

Reliability

The PMSM’s totally-enclosed design enhances its reliability as internal contamination (e.g. dust clogging) and ingress of water is eliminated. This reduces the possibility of motors getting overheated. PMSM motors also do not use a commutator, nor require ventilation fans as only natural cooling is needed.

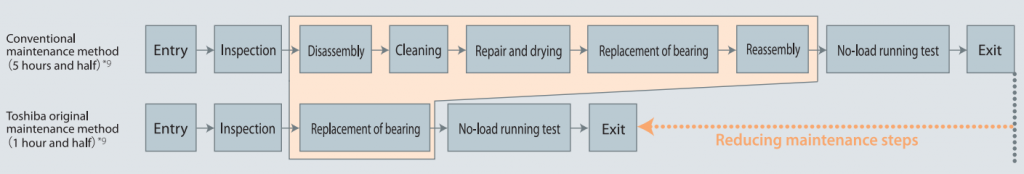

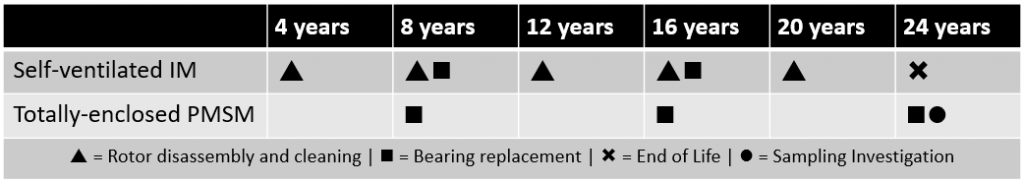

Reduced Maintenance

Maintenance costs are also lowered since PMSMs require bearing change out every 8 years instead of 4 with the current system. The fully enclosed PMSM motor itself is maintenance-free and keeps out dirt, which translates to labour and material saving for traction motor maintenance.

Quiet

Compared to the conventional open self-ventilating induction motor (IM), the enclosed structure of the PMSM allows for a 12 dB reduction of ventilation noise throughout all speed ranges.

Engineering Work

Toshiba supplied the main electrical equipment, consisting of the IGBT-VVVF traction inverter, a high-speed circuit breaker, a filler reactor, and a PMSM motor. J-TREC was in charge of remodelling the layout of underfloor components and offering on-site guidance for the construction work. Local firm SMT Rolling Stock was contracted for the provision of construction equipment and installation work. Singapore Rail Engineering / Railise supervised works.

The retractioning work was carried out at SMRT Bishan Depot’s Main Workshop.

Project Termination

In August 2016, the Land Transport Authority (LTA) and SMRT agreed to transition all existing rail lines to the New Rail Financing Framework (NRFF), in which the Government assumes responsibility for the expansion, replacement and refurbishment of all operating assets, including trains. A month later, in September 2016, the LTA announced its intention to replace all 66 first-generation C151 trains with brand-new ones, favouring the procurement of new trains over continuing to refurbish old trains, despite SMRT already being committed to the installation of the new PMSM propulsion system.

As a result of the NRFF and changes to SMRT Corporation’s management structure, Singapore Rail Engineering’s mid-life upgrading work was sidelined as SMRT pivoted towards focusing on subway operation and maintenance engineering. Unlike the C651 mid-life upgrading project that was formally terminated, SMRT is not known to have made any media statements confirming the end of its C151 upgrading efforts, with projects updates simply coming to a halt.

In November 2016, a Lianhe Zaobao article quoted Mario Favitas, Managing Director of Singapore Rail Engineering, saying that the C151 retractioning project would still carry on, and benefit the reliability of C151 trains prior to the introduction of their replacement trains, in what appears to be the last public update on the retractioning project.

The last check of Railise’s website in 2018 stated that “all 64 trains would be refurbished by 2020”. The company has since been struck off, and its website has also been taken down.

The contract for 66 replacement R151 trains would eventually be awarded to Bombardier in July 2018, and fulfilled by Alstom which fully acquired Bombardier Transportation in January 2021. Trains arrived in Singapore from 2022 onwards.

List of upgraded trains

| Trainset | Entered service with PMSM |

| 025/026 | 6 July 2017 |

| 055/056 | 30 July 2015 |

| 065/066 | 8 March 2017 |

| 095/096 | 15 August 2017 |

| 109/110 | 27 April 2017 |

| 131/132 | 30 July 2015 |

Information source: SGTrains Forums

Scrapping of refurbished trains

Main article: Decommissioning of C151 trains

Scrapping of PMSM-retrofitted C151 trains began in March 2022, with four train cars of 095/096 scrapped over two weekends in March. The remaining two train cars (3095 & 1095) were transported to Changi Exhibition Centre for the filming of an upcoming Mediacorp production.

Gallery:

Video:

Gallery:

Related Articles:

References:

- News Release (4 Jul, 2013): Toshiba’s Permanent Magnet Synchronous Motor Selected for Singapore Trains | News | Toshiba (global.toshiba) [Accessed 21 Mar 2022]

- 東芝、シンガポールのSMRTからPMSM受注…C151系396両分の走行装置を更新 | レスポンス(Response.jp) [Accessed 21 Mar 2022]

- J-TREC、ウクライナとシンガポールの車両改造設計を受注 | レスポンス(Response.jp) [Accessed 21 Mar 2022]

- シンガポール地下鉄 SMRT − C151 主回路更新改造− J.TREC Technical Review Vol.4 2015.12

- Toshiba and SMRT form traction JV – International Railway Journal; New York Vol. 54, Iss. 11, (Nov 2014): 23.

- Singaporean retractioning project pays dividends – International Railway Journal; New York Vol. 56, Iss. 7, (Jul 2016): 40,42-43.

- SMRT engineering subsidiary eyes international expansion – International Railway Journal

- Features & Benefits | Railise – PMSM System Technology (archive.org) [Accessed 21 Mar 2022]

- Older SMRT trains to get makeover for better ride, Singapore News & Top Stories – The Straits Times [Accessed 21 Mar 2022]

- SMT Group | Our Services [Accessed 21 Mar 2022]

- SMRT KHI C151 Refurbishment Project | Railise – PMSM System Technology (archive.org) [Accessed 21 Mar 2022]

C151A,B,C & CR151 may have PMSM & UOL in the future

Quite unlikely, LTA would probably just get

Alstom-CRRC Nanjing Puzhen to do any possible refurbishment to standardise all the parts and maintain commonality across the entire NSEWL fleet.

Haha LTA love to waste money and make wrong choices than later blame it on commuters and ridership etc……..