| Singapore Rail Test Centre |

|

|

|

| Location | 450 Jalan Ahmad Ibrahim, Singapore 639932 |

| Opened | 2 Nov 2023 (Phase 1 / High-Speed Test Track) 2025 (Phase 2 / Full Completion) |

Singapore Rail Test Centre (SRTC), formerly known as Integrated Train Testing Centre (ITTC), is a railway testing facility in Singapore, commissioned by the Land Transport Authority (LTA). The 50 ha site is situated at the former site of the Raffles Country Club, and enables the testing and commissioning of rolling stock and rail subsystems for both new and existing rail lines.

First announced on 24 April 2019, construction then began on 17 March 2021. The facility was originally planned to open in two phases; the first by end-2022 to receive new trains and systems for Circle Line 6. Full completion is expected by end 2024.

In an update by the Land Transport Authority to The Straits Times in November 2022, the completion of Phase 1 and Phase 2 was delayed to 2023 and 2025 respectively.

The first phase of SRTC was completed on 2 November 2023.

Introduction / History

ITTC was first announced on 24 April 2019 by Minister for Transport Khaw Boon Wan. With a capital cost estimated at several hundred million dollars, the facility was expected to enable more robust integrated testing of new railway systems before their implementation on operational lines. Such a facility would also deepen local engineering capabilities in the railway industry.

On 17 April 2020, Contract 190 for the design and construction of the ITTC was awarded to GS Engineering and Construction Corp (GS Engineering), at a contract sum of S$639.5 million. Construction started on 17 Mar 2021 with a groundbreaking ceremony officiated by Minister for Transport Ong Ye Kung. The first phase was originally targeted for completion by end-2022, in time for the testing of Alstom Metropolis C851E trains for Circle Line 6 in 2023. Full completion was originally expected by end 2024.

Facilities

SRTC is designed as a common facility for all train testing services. As such, the test tracks are designed to be interoperable and they can accommodate all types of signalling and communication systems used across the MRT network. It will also be equipped with both third-rail and overhead catenary power systems to allow for concurrent testing of trains and systems from different MRT lines.

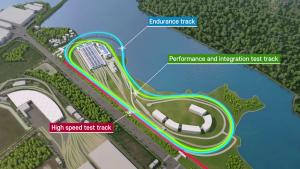

To facilitate a comprehensive range of testing modules, SRTC houses three separate types of tracks for specific safety-critical tests:

- Endurance Test Track

3km Loop track with gradient changes for train performance testing - Performance and Integration Test Track

2.8km Looped track with a branched ‘S-shaped’ track - High-speed Test Track (HSTT)- completed on 2 Nov 2023

Straight high-speed track with minimal curvature and gradient, for dynamic speed testing of up to 100km/h; Effective track length of 3km. Also comprises of one physical platform & two virtual platforms

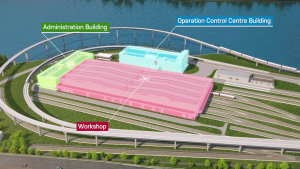

In addition to the roughly 11 km of test tracks, SRTC includes the following facilities:

- Administration Building

- Operations Control Centre (OCC)

- Train Maintenance Workshop

- Train Refurbishment Workshop

SRTC was designed by GS Engineering in cooperation with Korea’s state-run Korea Railroad Research Institute (KRRI). It is modelled after similar rail testing centres in Germany, Korea and Japan, all of which have extensive rail networks.

Key Benefits

The Integrated Train Testing Centre (ITTC) supports ongoing efforts to renew, upgrade and expand the rail network in Singapore; sustaining rail reliability, and deepening core rail engineering capabilities in Singapore.

Firstly, the ITTC allows for robust integrated testing of trains and their associated systems before they are deployed on operational lines. This approach frees up precious engineering hours for other activities, such as railway maintenance, and reduces the need for Early Closures and Late Openings in the future.

In addition, the LTA also expects to be able to speed up the diagnosis and rectification of faults with the ITTC, as troubleshooting can now be done locally. Over time, the ITTC would grow into a hub for LTA and the local rail industry to develop deeper Operations and Maintenance competencies and achieve engineering excellence.

The facility also provides railway workers with training opportunities, allowing for a first-hand understanding of the intricacies of new rail systems before they are deployed. The rolling stock facility at the ITTC can carry out mid-life train refurbishment projects. Furthermore, the ITTC can also serve as a testing ground for the local rail industry to evaluate new railway infrastructure, develop proofs-of-concept, as well as to conduct research and development into railway technologies.

Renaming of ITTC to SRTC

SRTC was first introduced as the new name for ITTC in the LTA Annual Report 2022/2023.

Trains Tested at SRTC

On the completion of Phase 1 of SRTC on 2 November 2023, the first two Alstom Metropolis C851E trains (Circle Line 6 trains) were undergoing testing and commissioning works.

A total of 23 trainsets are being delivered to support the Circle Line Stage 6. However, the first C851E train was delivered to Kim Chuan Depot instead in March 2022 as SRTC was not ready yet. The train was later transported to SRTC in 2023.

Construction

| 31 May 2019 | Tender released: Contract 190 – Design and Construction of Integrated Train Testing Centre Bids submitted by GS E&C and John Holland/McConnell Dowell (Joint Venture) |

| 17 April 2020 | GS Engineering and Construction Corp awarded the $639.5 million contract |

| 17 March 2021 | Construction begins; groundbreaking ceremony held |

| 2 November 2023 | Completion of First Phase of the Singapore Rail Test Centre – High-speed test track |

| 2025 | Projected Phase II opening – Endurance test track, Performance and Integration test track, Administration Building, Operations Control Centre Building and workshops |

Phase 1 which includes the construction of the high-speed test track, was completed on 2 Nov 2023 (originally Q4 2022) while the rest of the facility is would be fully operational by 2025 (originally end 2024) with the completion of the two remaining test tracks, the Administration Building, Operations Control Centre Building and workshops.

Renders

Overview (Nov 2023)

Track Connection to East West Line

A quotation request for Trial Trenches Work for Design and Construction of Rail Viaduct Link between Tuas West Extension and Singapore Rail Test Centre (Reference No. CQ23150) was raised by the Land Transport Authority on 1 November 2023. The request closed on 15 Nov 2023.

On 25 Apr 2024, a tender was called by the Land Transport Authority for the Design and Construction of Rail Viaduct Link between Tuas West Extension and Singapore Rail Test Centre (Contract 1906).

Testing Centres in other countries

Railway Testing Centres in other countries are built for the same reasons; as a way to rigorously test new railway technologies without the constraints of commercially-used rail lines. Apart from rolling stock, Testing Centres can accommodate all sorts of railway technologies, such as track or catenary components. They can be either privately-owned or state-owned.

Test Centres are also located in close proximity to train manufacturing facilities for testing prior to delivery. Many types of rolling stock which have been delivered to Singapore have been photographed in Testing Centres at their region of manufacture.

Promotional video

References

- Speech by Minister Khaw Boon Wan at the visit to SMRT’s New North-South and East-West Line (NSEWL) Operations Control Centre (OCC) at Kim Chuan Depot

- New Integrated Train Testing Centre for Greater Rail Reliability – LTA

- Factsheet: Singapore’s Integrated Train Testing Centre to be Fully Operational in 2024 – LTA

- GS E&C inks deal to build ITTC in Singapore by 2024 – The Korea Times

- $640m train testing centre delayed by a year, first phase to open in 2023 – The Straits Times

- Completion of First Phase of the Singapore Rail Test Centre – Land Transport Authority

In my opinion, linking up the EWL with the test centre is only for the convenience of not having to use trailers to transport the new NSEWL trains between the test centre and the depots.

It may not be required, and it will mean that next time cannot extend the EWL further.

The western catchment area, now no plan for new civilian settlement, doesn’t mean next time may not have.

We really should keep the EWL overrun viaducts at Tuas Link available, so that next time if there is a justification to extend the EWL further, we can still do it.

I think not many countries have dedicated test facilities in Asia. There’s one in Beijing for sure, but that’s all I can recall. South Korea and Japan performs trial runs on commercial lines.

South Korea also utilises a dedicated testing facility in Cheongju City from 2019. The facility has been built by GS Engineering, the same company taking charge of the construction of ITTC.

Several newly-built rolling stocks for Seoul Metro and other regional rail operators are seen to undergoing a test run on there.