The C151B Proof-of-Concept (POC) Train was revealed at a media preview at Bishan Train Depot held on 18 December 2025. The train aims to improve reliability and commuter comfort by testing new monitoring systems to identify faults before they happen.

The trial, initiated via a Memorandum of Understanding (MoU) by SMRT and CRRC Sifang in November 2024, aimed to test the latest reliability-centred capabilities on a fifth-generation C151B train.

The train set, 649/650, was shipped to CRRC Sifang’s facilities in Qingdao, China, in December 2024, where it underwent retrofitting to incorporate component upgrades and modifications. The train subsequently returned to Bishan Depot in October 2025, where further testing and commissioning would be required before its return to passenger service, targeted for June 2026.

Following the trial of the POC train, SMRT will work with LTA to embody these solutions into 91 other fourth-, fifth- and sixth-generation trains (C151A, C151B & C151C trains) as part of their mid-life upgrades.

Special Train Livery

The train sports a special in-house livery illustrating SMRT’s vision for a smarter, more resilient future—rooted in national pride and powered by technology.

The design features a distinctive red and white livery on the train cars, both colours of Singapore’s national flag, marking the significant milestone of SG60 and underscores SMRT’s role in nation-building. Elegant line art of iconic landmarks adorns the sides of the train, celebrating SMRT’s achievement in connecting and moving communities since 1987.

Technology-inspired motifs fill the interior of the train, highlighting SMRT’s mission to leverage technology and innovation to improve train reliability and enhance commuter comfort for better journeys.

More sensors to detect potential issues

According to SMRT, approximately 180 new sensors were installed, in addition to the 300 already installed on each train. This real-time data is transmitted to a maintenance control centre at Bishan Depot, where these issues can be reviewed.

For simple faults, adjustments can be made while the train is operating. For more serious faults, the train may need to be recalled to the depot for further checks. Less serious issues can be rectified after revenue service hours, when the train has returned to the depot.

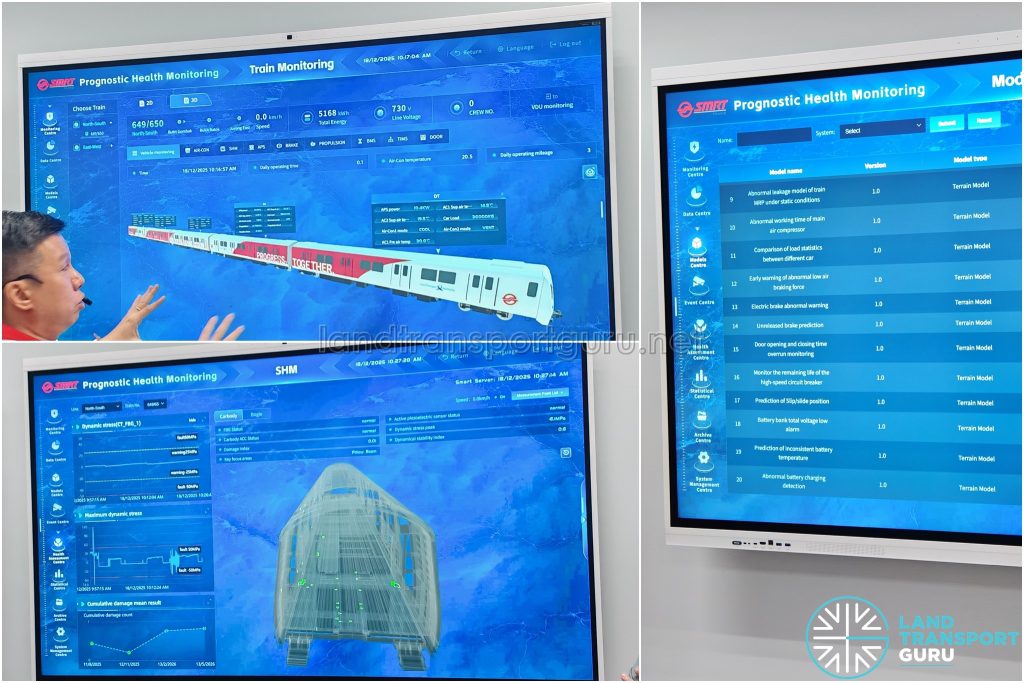

The data from the train is also augmented into 47 condition monitoring modules, i.e., ‘key indicators’, which aim to track abnormal conditions that can be identified by one or more sensor inputs. SMRT aims to fine-tune these models as the POC trial progresses.

Features in detail

Key features installed on the POC Train are:

1. Condition Monitoring (CdM) System

The Condition Monitoring System is a smart diagnostic system designed to continuously monitor the health and performance of critical train components and systems.

| Before | After |

| Train Information and Management System (TIMS), an integrated platform that monitors critical subsystems, only triggers alarms after component failures. | CdM System provides an additional layer of early detection, identifying potential issues before they trigger TIMS alarms. |

Benefits:

- Proactive approach keeps services running smoothly, ensuring a more reliable journey for commuters.

Improvements:

- Comprehensive Coverage:

Monitors all the critical components of the train, from power systems, air-conditioning systems, door control systems, to brake systems. - Smart Functions:

It performs diagnostics automatically and delivers immediate alerts on anomalies and potential faults. - Predictive Maintenance:

A built-in algorithm examines and diagnoses the train’s health. It also recommends that trains be withdrawn from service before affecting commuters’ journeys. - Improved Connectivity:

Real-time data flow between trains and ground teams via 4G/Wi-Fi; facilitates faster decision-making. - Future-Ready:

Supports condition-based maintenance and life-cycle cost optimisation through predictive analytics.

According to SMRT, this system is more advanced than those fitted on the seventh-generation NSEWL trains (Alstom R151).

2. Structural Health Monitoring (SHM)

Structural Health Monitoring (SHM) is the systematic process of using sensors and data analysis to provide continuous, real-time assessment of the train’s structural performance, such as the main structural components like car-bodies and bogies.

| Before | After |

| Structural integrity was assessed on an ad-hoc basis when required, typically when a train approaches mid-life. | SMRT is introducing a new capability to the train. By monitoring and trending micro-changes in the stresses and strains, SHM can enable timely engineering and maintenance solutions to ensure safety and reliability. |

Benefits:

- Faster intervention before potential faults occur.

Improvements:

- Targeted Monitoring:

Focuses on critical areas identified through finite element modelling. - Smart Sensors:

Uses a suite of sensors to measure stress, strain and vibration, to detect early signs of structural issues. - Predictive Insights:

Advanced algorithms analyse data to detect fatigue before problems occur. - Long-Term Reliability:

Data would be used to develop and refine engineering and maintenance solutions.

3. Air Conditioning and Ventilation (ACV)

The Air Conditioning and Ventilation (ACV) system is a critical component in ensuring commuter comfort and safety on trains.

| Before | After |

| The existing ACV system is ageing and unable to sustain its intended cooling capability. The refrigerant used also has a higher Global Warming Potential (GWP) than modern refrigerants. | The upgraded ACV system features modern, high-efficiency components designed for durability and reliability. It also uses a lower GWP refrigerant to reduce SMRT’s environmental impact. |

Benefits:

- SMRT will be better able to phase down the use of hydrofluorocarbons and maintain optimal temperature in the trains.

Improvements:

- Eco-Friendly Refrigerant:

Upgraded to a lower Global Warming Potential (GWP) refrigerant to meet global climate standards (Montreal Protocol). - Enhanced Condition Monitoring:

Embedded sensors detect filter blockages and leaks for proactive maintenance. - Improved ACV Reliability:

Design enhancements reduce compressor failures and refrigerant leakages.

4. Bogie Monitoring System (BMS)

The Bogie Monitoring System is designed to continuously monitor the condition of critical bogie components. A bogie is the undercarriage of a train, which houses the suspension systems, axles, gearboxes and wheels.

Key parameters tracked by the BMS include: wheel wear, axle load, temperature, vibration, alignment & structural integrity.

| Before | After |

| No on-board systems to monitor and provide feedback on the condition of critical bogie components in real time. | The Bogie Monitoring System enables predictive bogie maintenance by leveraging continuous data collection and advanced analytics. BMS detects early signs of degradation to enable timely intervention. |

Benefits:

- This system minimises unexpected downtime, keeps trains operating efficiently, and ensures a stable and comfortable ride for commuters.

Improvements:

- Real-Time Monitoring:

Combined temperature and vibration sensors track bearing health and trigger early warnings when abnormal signals occur. - Smart Algorithms:

Warning thresholds are established through controlled simulated testing, and algorithms are continuously refined using long-term operational data to improve accuracy in detecting potential issues.

After the Rotem and SRE episode, they aren’t deterred and are trying to convince the sceptics that such improvement works are doable when the money spent could be used to purchase na ew fleet of trains.

Even though the interior lights are dimmer , it saves current.

Improvements in comfort. Good. But notice there is no improvement to the noise generated while travelling. So same old noise we have endure even with all the improvements for years to come. It will good to do something about the noise.

Shouldn’t C151As be retired and replaced by R151s instead of Refurbishment? Can Someone Volunteer to Recommend LTA to cancel the C151A refurbishment?

B,not A

It’s C151B, but that comment is for the C151As which is not related here.

Money a lot is like that. To be honest, all these enhancements are not necessary.

It is a investment and opportunity cost . if it is not necessery , it will breakdown more easily and the cost will be higher .