The Volvo 7900 Electric is a low-floor, battery-electric city bus built by Volvo Buses for the European market. European bus operators are primary customers of the bus with units operating in Sweden, the Netherlands, the United Kingdom, Luxembourg and Poland.

Two (2) Volvo 7900 Electric buses were brought to Singapore in 2018 as part of the NTU-LTA-Volvo Autonomous Bus Trial and are retrofitted with autonomous driving hardware.

Background Information:

The Volvo 7900 range of integral city buses was introduced by Volvo Buses in 2011 when it was initially offered with a diesel or CNG engine in both rigid and articulated bus variants. The Euro VI engine range was offered starting in 2013, along with the diesel-hybrid variant known as the Volvo 7900 Hybrid.

Two newer propulsion systems were developed for the Volvo 7900. The Volvo 7900 Electric Hybrid, launched in September 2014, is a plug-in hybrid bus designed to run mainly in electric mode. The Volvo 7900 Electric was a battery-electric version unveiled in October 2015, powered solely by batteries and electric motors. Both versions are complemented by Volvo’s Opportunity Charging System, a rapid charging station at the end stations of a bus route that quickly tops up a vehicle’s battery via an overhead charging system.

In March 2023, Volvo Buses announced that it would be ending production of complete buses and coaches in Europe, switching its European focus solely to chassis production. Volvo Buses’s plant in Wroclaw, where the Volvo 7900 is built, will be closed in Q1 2024 after all existing delivery orders are fulfilled. Production of the Volvo 7900 will be moved to Egypt, where bus bodybuilder Manufacturing Commercial Vehicles (MCV) will take over the production of Volvo’s 7900 range under licence.

Electric Technology:

Volvo touts the 7900 Electric bus as being silent and comfortable. Contributing little noise and zero tailpipe emissions, the bus is ideal for urban environments and compliant with existing low-emission and low-noise zones within European cities. The Opportunity Charging System is also touted as superior to overnight charging, allowing Volvo to use a smaller and lighter battery pack, which improves bus capacity. The Volvo 7900 Electric is available with a choice of 150, 200 and 250 kWh batteries.

During normal operations, energy stored within the onboard batteries is released to power the electric motors and onboard systems. The electric motors drive the rear wheels via a simple two-speed automated transmission, and regenerative braking helps recover some mechanical energy back into electrical energy.

Charging System:

The Volvo 7900 Electric offers a fully-automatic fast-charging sequence in just six minutes via a roof-mounted conductive charging system, paired with the OppCharge opportunity charging interface. In Singapore, the ABB HVC 300P fast-charge system was installed to facilitate the Volvo 7900 Electric Autonomous Bus Trial.

Supplied by Swiss-Swedish engineering group ABB, OppCharge is an open and competition-neutral interface seeking to accelerate the adoption of electric buses by being compatible with multiple bus manufacturers, hence offering operators choice and flexibility of buses without the need to modify existing charging infrastructure. These overhead pylon chargers with extendable pantographs are usually installed at the end stops of bus routes, allowing buses to quickly receive a full charge in-between trips.

Charging is fully automatic and secured by a two-way WiFi communication sequence. The driver gets a clear indication in order to stop within the specified ± 200 mm from the reference point. The charging sequence is started by activating the parking brake, and the driver can interrupt it at any time.

In addition, the Volvo 7900 Electric can also be charged via cable. Combined Charging System (CCS), which is the European standard for charging of electric vehicles from the mains grid, is more suited for high-power charging when buses are stationed at the Depot.

In Singapore, a portable plug-in charger was set up to facilitate the charging of the Volvo 7900 Electric Bus during the initial trial period, whilst the ABB charging stations were built.

2023 Status:

As of 2023, the buses appear to no longer operate for trial purposes, with exterior autonomous equipment (such as LIDAR sensors) removed from one unit.

See Also: Autonomous Buses in Singapore

NTU-LTA-Volvo Autonomous Bus:

Main Article: NTU-LTA-Volvo Autonomous Bus Trial

On 11 January 2018, an agreement was signed between the Nanyang Technological University (NTU) and Volvo Buses for the development of an autonomous bus, also known as a driverless bus. To enhance Singapore’s land transport system, new forms of shared mobility in the form of autonomous vehicles are envisioned to improve the first and last-mile commute.

Two Volvo 7900 Electric buses were being brought into Singapore as a testbed for development, with the first arriving in Singapore in late October 2018, and the second arriving several months later. The buses bear the registration numbers RD3162L and RD3169T respectively.

| Basic Technical Specifications | |

| Motor / Battery | Electric Motor paired with Lithium-Ion batteries Electric motor rated at 160 kW / 400 Nm Can be charged via OppCharge or CCS Type 2 (250 kWh charge only via CCS) Operating range up to 200 km depending on topography and driving conditions |

| Transmission | Volvo 2-speed automated transmission |

| Bodywork | Volvo Integral Bodywork (TBC) Assembled in Wroclaw, Poland and shipped to Singapore fully assembled |

| Autonomous Technology | – LIDAR sensors (Light detection and ranging) for charting, positioning and scanning areas around the bus – Stereo-vision cameras for 3D image capture – Advanced Global Navigation Satellite System for location accuracy of up to 1cm – Automatically regulated steering, gear changing and speed control |

| Other Features | – Mobitec Electronic Display Sign (EDS), orange LED matrix design – Autonomous driving activation button and emergency cutoff next to dashboard – Rooftop charging rails for inverted pantograph charging – Valeo REVO-E electric air-conditioning system – Licensed carrying capacity: 36 seated and 57 standing passengers |

The Volvo 7900 Electric is designed around the concept of opportunity charging and is available with a choice of 150, 200 and 250 kWh batteries. In contrast, the BYD K9 previously trialled on Singapore roads had a battery capacity of 324kWh, but the batteries take up much more space on the bus, adding to the overall vehicle weight.

In its European specification, the Volvo 7900 Electric is a fully-low-floor bus with up to three doors. For the buses supplied for the trial in Singapore, RD3162L only has a front entrance door, while RD3169T has a conventional two-door layout (front entrance and middle exit doors).

The autonomous bus trial:

The project to develop the Autonomous Bus is led by the Nanyang Technological University (NTU)’s Centre of Excellence for Testing and Research of Autonomous Vehicles (CETRAN) in collaboration with Volvo Buses. CETRAN was set up by LTA and JTC in partnership with NTU and was operational in the 4th quarter of 2016.

The bus will be tested at CETRAN’S 1.8-hectare test facility within the Jurong Innovation District. Opened in August 2016, the test circuit emulates a multitude of urban scenarios, including an area with simulated rainfall. This would allow a safe environment for rigorous testing of the bus before it enters public roads.

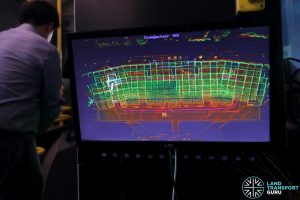

The buses will be equipped with GPS along with a Light Detection and Ranging (LIDAR) laser system for charting, positioning and scanning the area around the vehicle. The bus will also automatically regulate its steering, gear changing and speed.

Volvo started developing autonomous technologies on its cars in 2006 and embarked on a large-scale trial of self-driving cars as part of its Drive Me project conducted in Gothenburg, Sweeden. The research cooperation in Singapore represents Volvo’s first foray into autonomous uses for buses and public transport.

While one unit was stationed at CETRAN, the second Volvo 7900 Electric bus was tested at SMRT Woodlands Bus Depot to fine-tune the autonomous technology for conventional depot operations. The objective is to ensure that autonomous buses are able to charge their batteries, drive through the depots to the vehicle wash and park – entirely autonomously.

Exterior:

The Volvo 7900 range of buses share the same integral bodywork. A suite of autonomous driving-enabling sensors, comprising cameras, LIDAR sensors and stereo-vision cameras, are installed around the bus.

Interior:

The bus features 35 permanent seats. Being a low-floor bus, the bus offers step-free access from entry/exit doors until the last row of seats.

Grab poles are located on both sides of the aisle. All seats also have hand grips to provide commuters with additional support.

Bus stopping bell-pushes are located around the bus cabin, mounted to stanchion poles. Emergency hammers are also located on pillars in-between windows.

The bus features a single wheelchair bay located on the left side of the bus, ahead of the exit door. It accommodates one passenger-in-wheelchair (PIW) and is equipped with a wheelchair backrest, PIW alighting bell and securing belts.

A manual wheelchair ramp is installed at the front door.

As the bus is built to European specifications, various features unique to temperate climate operations have been installed. The bus is fitted with hopper windows for ventilation, and floor heaters for the winter.

A developer rack is installed at the facing seats behind the driver cabin. The rack houses the electronic hardware that operates the autonomous features of the bus, acting as an interface with the bus’ onboard systems.

The autonomous bus controller software relies on sensor fusion from the bus’ onboard sensors (LIDAR, RADAR, cameras, ultrasonic sensors, INU and GNSS) to achieve environmental perception, object detection and tracking, map generation and vehicle control.

Driver’s Compartment

Fitted to the left of the conventional dashboard are controls for manipulating the autonomous software, including a start/stop button and a tablet screen.

Other features

The bus features an emergency exit on the offside; a feature not mandatory for buses in Singapore. Selected seats are equipped with USB charging ports.

Two units were brought in for the autonomous trial: RD3162L and RD3169T, both built to default European specifications. The former is only equipped with one passenger door at the front of the bus, while the latter uses the conventional two-door layout featuring the exit door in the middle.

Both entrance and exit doors are electrically-actuated conventional inward-swinging leaf doors supplied by ISAF Bus Components.

Autonomous Driving

Autonomous driving capabilities were exhibited to the public at the 26th ITS World Congress 2019 held in Singapore, where the bus plied a test route within The Float @ Marina Bay.

Gallery: (Before restickering)

Gallery: (After restickering)

Gallery: (ITS World Congress 2019)

Gallery (2021):

Gallery: (2023)

See Also: NTU-LTA-Volvo Autonomous Bus Trial

See Also:

- BYD K9

- Go-Ahead Singapore trials BYD Electric Bus

- Volvo 7900 Hybrid

- Volvo Diesel Hybrid Buses procured by LTA

External Links & References:

- Volvo Buses History – Volvo Buses [Accessed 11/01/18]

- New Volvo 7900 Electric offers greater range and flexibility – Volvo Buses

- Volvo 7900 Electric – Volvo Buses

- Busworld Kortrijk 2016 – Bus & Coach Buyer

- OppCharge website

- Autonomous Driving – Volvo Cars

- Driverless electric buses to be tested from 2019 in collaboration between NTU, Volvo – Channel NewsAsia

- Volvo and NTU to trial electric buses in Singapore – Volvo Buses

- Volvo’s Autonomous electric buses in Singapore – Volvo Buses

- Volvo signs agreement with MCV for production of 7900 range – CBW (cbwmagazine.com)

- Volvo Bus partners with MCV for production e-buses | Busworld Europe 2023

Back to Bus Models

This bus looks like A22.

So the hybrids will goes to SBST abd full electric goes to SMRT,Woes to TTS & GAS.