Related Article: CBTC Implementation: A review

Looking for a more in-depth perspective on the CBTC implementation and its challenges? Check out our new article, CBTC Implementation: A review, for a technical and policy perspective on the CBTC rollout, along with our own opinions.

Communications-based train control (CBTC) is a moving block type railway signalling system that relies on continuous telecommunications between the train and trackside equipment for train management and control. The CBTC system on a train communicates real-time location and speed data with the trackside computers, which establish a safety envelope in which a train is allowed to operate.

In Singapore, the CBTC signalling system is used on the North East Line, Circle Line, Downtown Line and the Thomson-East Coast Line. The North South Line and East West Line, being the oldest lines in the network, was most recently upgraded from a speed-signalled Fixed Block signalling system to a new CBTC signalling system, in use since Year 2017 and 2018 for both lines respectively.

In comparison to the old Fixed Block system used on the CBTC system on the NSEWL, the CBTC was able to reduce train intervals from 120 seconds to 100 seconds, allowing for a 20% increase in capacity. This resignalling project was accompanied by the delivery of 57 new trains (45 C151B and 12 C151C trains) for both lines, with deliveries concluding in 2019. In addition, CBTC is able to support bidirectional train operations on a single track, enabling trains to be diverted onto another track when there is a fault on one track.

CBTC was implemented on the NSL from 29 May 2017, the Tuas West Extension from 18 June 2017, and the full EWL from 27 May 2018. The Bukit Panjang LRT will be upgraded to CBTC by 2024.

Fixed Block system:

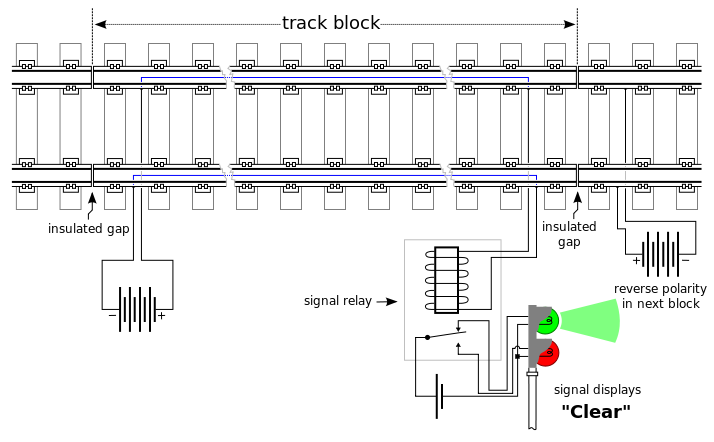

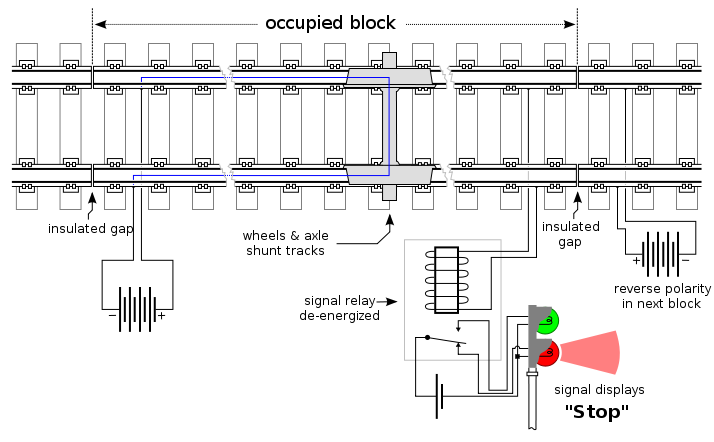

The old Fixed Block system divides tracks into many smaller sections known as ‘blocks’ roughly 200 metres in length. Each block can only be occupied by a single train at any given time, and a block is considered occupied even if only a small part of the train is in it. This is due to the working principle of track circuits, which detects if a train is within a block, but not its actual position.

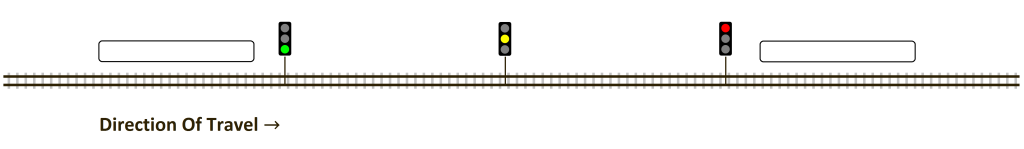

To maintain a safe distance between trains, a buffer of one block is added to the rear of each train, ensuring that a train coming from the rear has an adequate distance to brake in time to avoid a collision.

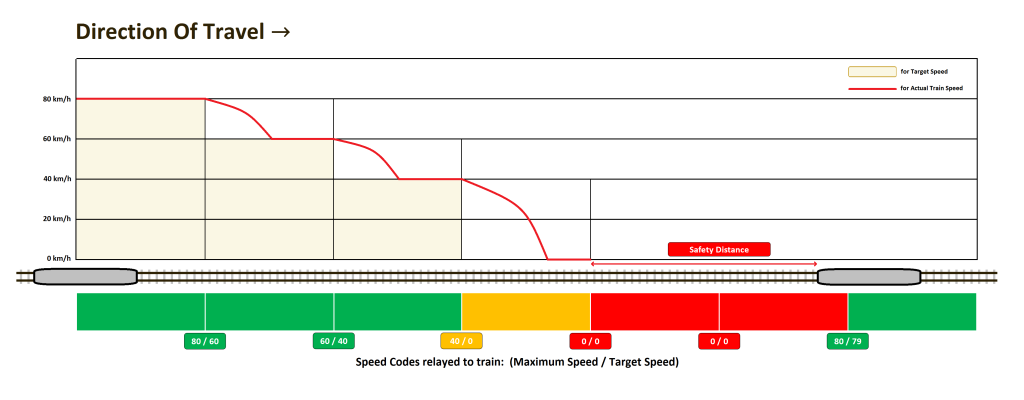

The North South Line and East West Line formerly used a speed-signalled Fixed Block system which transmits the maximum speed and target speed to any passing train, depending on the distance to the train ahead or any speed restrictions in place. The information is displayed in the driver’s operating console.

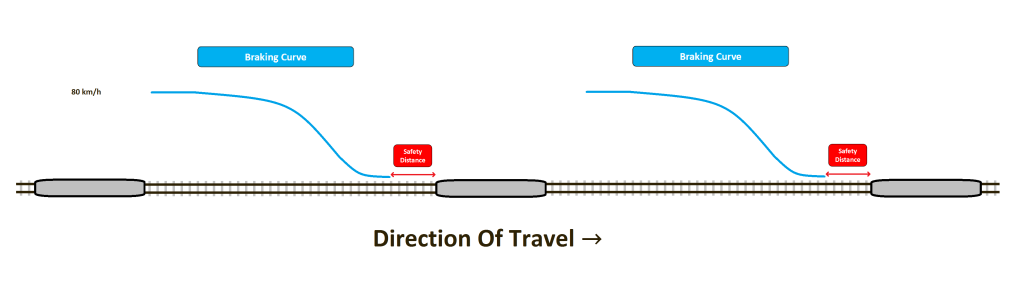

As evident in the graph, the fixed-block signalling system allocates reduced speeds behind each train, resulting in a tiered speed reduction process resembling a flight of steps.

CBTC Moving Block system:

In the newer CBTC signalling system, the exact position, speed, travel direction, braking distance and various other parameters of each train is transmitted wirelessly to wayside (another term for trackside) computers. Gathering information from nearby trains, the wayside computers establish protected areas, each one called a Limit of Movement Authority (LMA), up to the nearest obstacle (such as the train in front).

As such, trains continuously receive information regarding the distance to the preceding train and are then able to adjust their safety distance accordingly. This form of moving block signalling does away with the older fixed-block system relying on track circuits.

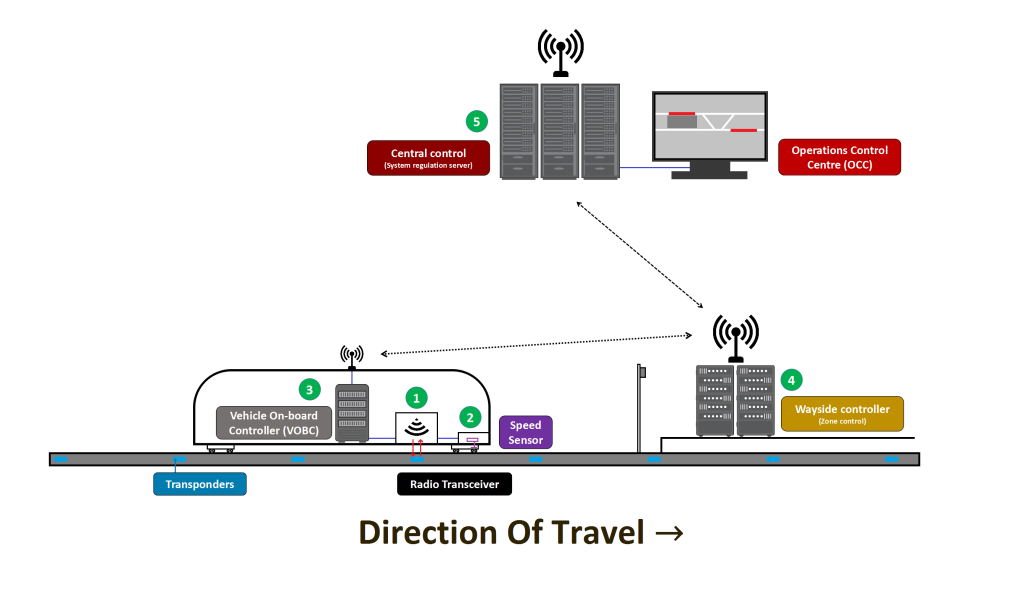

As part of the CBTC systems, transponders are installed on the track at regular intervals, which return radio signals emitted from the train when a train passes over it. Trains are also fitted with a speed sensor. Like distance markings on a road, the train is able to identify its exact position by identifying the last transponder encountered, and then adding the distance travelled after encountering the transponder. This task is performed by the Vehicle On-board Controller (VOBC).

Next, the VOBCs transmit data wirelessly to and from Wayside Controllers, which are computer systems at every station. Paired with Wayside Radio Units, which are trackside antennas located near each train station, the wayside controllers process the data from trains and calculate the Limit of Movement Authority (LMA) for each train. The subsystem can also set routes based on commands received from the Operations Control Centre

Finally, the wayside controllers transmit data to and from Central Control, the Man-Machine interface located within the Train Operations Control Centre. Operators can monitor the track status and train positions, and adjust headways, schedules and train routeings where necessary. The system can also support running trains to a prescribed timetable or train interval as part of the ATS feature. Fibre-optic cables are used to transmit large amounts of time-critical data between Wayside Controllers and Central Control.

CBTC signalling systems work in tandem with other critical rail subsystems such as Automatic Train Protection (ATP), Automatic Train Operation (ATO) and Automatic Train Supervision (ATS). In general, ATP governs the train speed, ATO manages the automated operation of trains, and ATS tracks and schedules trains. Computer-based interlocking (CBI) is used to ensure points and signals are being set in the correct configuration.

Although CBTC operation does not require conventional track circuits, they are still installed as a fall-back measure to ensure train detection and protection are independent of the radio communication system.

Advantages of CBTC

The CBTC system uses existing track space more efficiently, safely reducing the space between trains, and hence making room for additional trains on the same line. On the North South Line and East West Line, the CBTC upgrade brought down waiting times 120 seconds to 100 seconds, allowing for a 20% increase in capacity. This was accompanied by the delivery of 57 new trains (45 C151B and 12 C151C trains) for both lines scheduled for 2019, greatly reducing peak hour congestion on these lines in the years to come.

The system can also adjust train speeds, reduce train bunching and recover from delays. Trains are also able to operate on all tracks in both directions safely. This offers more flexibility for trains to switch between tracks when there is a fault on one stretch of track.

Additionally, the CBTC system can support Unattended Train Operation (UTO), which is used on the North East Line, Circle Line and Downtown Line and do not require an operator on board, although rail operators SBS Transit and SMRT Trains elect to keep a train attendant onboard in the event of a disruption.

Previously on the North South Line and East West Line, trains on fixed-block signalling use Semi-automatic Train Operation (STO), with the driver closing the doors at every station and operating the train manually during a disruption. After the CBTC upgrade, both lines will use Driverless Train Operation (DTO), where doors will close automatically. The system will not require input from the Train Operator unless in the event of a disruption.

The CBTC is advantageous even in wet weather, where trains will automatically adopt a wet weather braking profile when the rails are wet, without the need for manual driving. In the old signalling system, the braking forces demanded by the Automatic Train Control (ATC) are optimised for dry weather and would cause the wheels to slip during wet weather, resulting in platform overruns. As such, Train Operators manually drive the train in Protected Manual Mode, PMM (also known as Coded Manual, CM), resulting in a more jerky ride. Under CBTC, trains in wet weather will adopt a more gentle braking profile to avoid wheel slippages, and the additional time taken between stations are automatically factored into the scheduling system.

NSEWL Ride Experience

For the average commuter on the North South and East West Lines, the CBTC signalling system may offer no difference to the commuting experience. However, when guided by the CBTC signalling system, trains will operate more smoothly with less need for abrupt stops along the line when there is a slower moving train in front. The braking profile when approaching a station will be similar to other CBTC-fitted driverless lines (North East, Circle and Downtown lines), smoothly braking to a low speed, coasting for a short distance then finally braking again to line up precisely with the Platform Screen Doors.

Additionally, doors will close automatically under the CBTC signalling system. During the CBTC rollout, SMRT had put up notices and billboards within NSEWL stations, reminding commuters not to rush for the train after the “Doors are closing” chime is heard.

North South Line Implementation

Main Article: Travel Advisory for North South Line Commuters

Live CBTC Testing began in the late hours of 28 March 2017, during the last hour of revenue service, when all trains were stopped at around 11pm to facilitate the switch to the new system. These tests were carried out across the next few days, for a total of 10 sessions. Full-day testing of the system commenced on 16 April 2017 (Sunday) and continued every Sunday for the next two months for a total of 7 sessions.

Full-day weekday testing (akin to full implementation) of the CBTC system commenced on 29 May 2017, deliberately timed with the start of the month-long June school holidays to lessen the inconvenience on students. The full fleet of 124 trains was tested, as compared to 55 trains during Sunday testing. The LTA highlighted issues, including the platform screen doors not opening, and trains overshooting their station. In addition, stopping trains accurately at overground stations was challenging during wet weather, especially when having to work with four different types of trains on the NSL. As such, the braking profiles had to be fine-tuned for wet weather operation.

The system is expected to be fully commissioned by March 2018.

East West Line Implementation

After the open house two days prior, partial implementation of the CBTC commenced on 18 June 2017 with the opening of the Tuas West Extension. Originally scheduled to open in end-2016, it was delayed to allow for more time for testing of the signalling system. Trains switched from the old Westinghouse fixed-block system to the Thales CBTC system at Pioneer Station (in both directions).

However, in the wake of a train collision incident at Joo Koon Station on 15 November 2017, CBTC and legacy signalling systems were physically separated until CBTC resignalling works on the entire EWL were complete. The link between Joo Koon and Gul Circle was broken and necessitated a transfer via shuttle bus. The incident marked a crucial turning point in the CBTC rollout, where shortened operating hours (comprising early closures, late openings and Sunday full-day closures) were implemented across sections of the EWL to accelerate resignalling works. As a result, the completion of CBTC installation on the EWL was brought forward to June 2018.

Full-day testing of the system commenced on 29 April 2018 (Sunday) and continued every Sunday until May 2018 for a total of 5 sessions. Full-day weekday testing (akin to full implementation) of the CBTC system commenced on 27 May 2018, the last day of scheduled weekend testing. This was deliberately timed with the start of the month-long June school holidays to lessen the inconvenience to students.

See Also: Shorter Operating Hours for Rail Renewal Work

CBTC Simulation Facilities

In the wake of the train collision incident on the EWL attributed to a CBTC software fault, the LTA worked with signalling system providers to set up simulation facilities at selected train depots. These new facilities are equipped with hardware and software similar to the actual signalling systems operating on the rail lines.

This allows software patches to be rigorously tested under a controlled environment and with local conditions before the software is rolled out to the mainline. Doing so increases the robustness of testing and minimises potential disruption to passenger service. As the facilities replicate the functionality of the mainline signalling system, they are also a useful training tool for LTA and the rail operator’s engineers to gain valuable practical experience on how to efficiently diagnose and rectify system faults during day-to-day operations and maintenance.

Starting with the North-South & East-West Lines, CBTC simulation facilities are expected to be rolled out across all CBTC-equipped line depots, as follows:

| MRT Line | Location | Simulation Facility Completion Timeline |

| North-South & East-West Lines | Bishan Depot | Completed end 2018 |

| Downtown Line | Gali Batu Depot | Progressively from end 2019 to end 2020 |

| Thomson-East Coast Line | Mandai Depot | Progressively from end 2019 to 1Q 2021 |

| North East Line | Sengkang Depot | Progressively from mid-2020 to end 2022 |

| Circle Line | Kim Chuan Depot | Progressively from 2Q 2021 to end 2022 |

Lines in use:

- North East Line, Circle Line: Alstom Urbalis 300 CBTC

- Downtown Line: Invensys (now Siemens) Trainguard Sirius CBTC

- North South Line, East West Line: Thales SelTrac CBTC

- Thomson-East Coast Line: Alstom Urbalis 400 CBTC

- Bukit Panjang LRT: Bombardier Cityflo 650 (Commissioning 2022)

Gallery:

Trivia: Track circuits

The track circuit system, which Fixed block signalling relies on, is unable to determine the exact position of the train within the track circuit section. The block will be registered as “occupied” even if only a very small portion of it is actually occupied.

Related Content:

- CBTC Implementation: A review – Land Transport Guru

- New CBTC Signalling System: 9 Things to Know – Land Transport Guru

- North South Line – Land Transport Guru

- East West Line – Land Transport Guru

- Tuas West Extension – Land Transport Guru

External Links & References:

- Communications-based train control – Wikipedia

- CBTC – Communication Based Train Control – Thales (PDF)

- SelTrac® CBTC communications-based train control for urban rail – Thales (PDF)

- Upgrading Singapore’s Signalling System – LTA Singapore – YouTube

- Factsheet: Simulation Facilities for Signalling System Testing – LTA

- Diagrams produced in-house unless otherwise stated