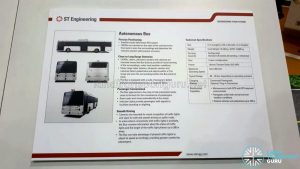

The ST Engineering-Linkker Autonomous Electric Buses are two battery-electric single-deck city buses introduced to Singapore roads by ST Engineering Land Systems (formerly ST Kinetics) in partnership with Finnish electric vehicle manufacturer Linkker. These buses are equipped for fully-autonomous operation, and can be charged via an inverted pantograph (OppCharge) or via charging cable.

There are two versions of this bus. The first bus, based on the Linkker 12+ city bus, features a low-entry layout with three doors. Similar to the earlier MAN 3-door Concept Bus, the rear door is accessed by a flight of steps from the rear passenger cabin. The second bus is based on the Linkker 12 LF, bearing a prototype bodywork first revealed by ST Engineering in October 2018.

Both buses were used for autonomous bus research and development between 2018 and 2022, including a four-month public trial at Jurong Island in 2021. With ST Engineering winding up its autonomous bus unit in late 2022, the future of these buses are uncertain.

Background Information:

On 10 April 2017, ST Kinetics (now ST Engineering Land Systems) announced that it will develop Autonomous Vehicle (AV) technologies and integrate them into two 40-seater electric buses. These prototype vehicles would undergo a three-and-a-half-year period of road trials expected to begin in mid-2020, with potential test grounds being Jurong Island and the National University of Singapore (NUS)’ campus. The eventual goal was to develop autonomous buses capable of running fixed and scheduled bus services for intra- and inter-town travel.

The initial testing would be conducted during off-peak periods in an industrial area (later revealed as Jurong Island) where the road infrastructure is less complex. As the autonomous buses are gradually equipped with more advanced capabilities, they will be progressively introduced to more complex trial sites.

The development and testing of the autonomous buses will aim to cover as many scenarios faced by bus feeder services as possible, to deepen understanding on the current state of the technology and to prepare for eventual full-scale operations in the future when the technology matures. In the longer term, it is envisaged that the trial could be extended to public roads in towns to enhance intra-town travel.

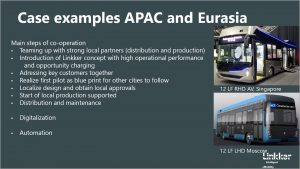

The three-door prototype buses are manufactured by Gemilang Coachworks, with electric drivetrain components and chassis from Linkker. The partnership was indicated in ST Engineering’s 2017 Annual Report, referred to as a “partnership with an Original Equipment Manufacturer (OEM) for electric buses to distribute electric buses in right-hand drive countries in Asia Pacific, including Singapore, Australia, Hong Kong, Indonesia, Malaysia, New Zealand and Thailand”.

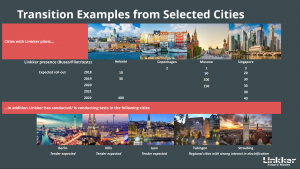

Separately, Linkker’s company brochures also indicated that it was involved in a project with a Singapore partner “with Autonomous Drive endgame”, and buses would be locally produced. Linkker also indicated its interest in delivering up to 325 buses over a 5-year period. The Finnish company has previously tested its buses domestically (in Helsinki, Espoo, Turku) and overseas in Copenhagen and Moscow.

In 2020, after the public reveal of the Linkker 12 LF in Singapore, more Linkker documents available online confirmed Linkker’s involvement in Singapore (and more specifically with ST Engineering).

Public Showcase

The Linkker 12 LF was first revealed in October 2018 by ST Engineering at a company event (Singapore Business Night) held at Singapore Expo. In October 2019, the bus was exhibited at the 26th Intelligent Transport Systems (ITS) World Congress, branded as the STROBO Series 12 Bus and bearing the Research and Development registration plate “RD3165D“.

There have been no known public showcases of the Linkker 12+ (RD3151T).

Autonomous Technologies:

To navigate autonomously, the buses use a satellite-based Global Positioning (GPS) System and a suite of short- and long-range sensors such as LIDARs, radars, ultrasonic sensors and cameras to scan and determine its location and immediate surroundings. For near objects, close-range radar and ultrasonic sensors detect objects within a 10m range and ensure that it is safe for the bus to move off. For further objects, the bus has radars and sonars that are able to detect other vehicles and pedestrians up to 150m ahead. Autonomous driving works in most weather conditions, with ST Engineering working to improve the autonomous buses’ ability to navigate in heavier rain conditions, up from the current 10mm/h to 30mm/h.

For smooth driving, cameras are mounted for visual recognition of traffic lights and signs for safe and smooth driving on public roads. In areas where connectivity is available, the bus receives information about the status and length of the traffic light phases

In summary, the features are:

- Precise Positioning

Global navigation satellite system and localisation sensors for precise positioning and navigation - Fast Charging Technology

Quick charging technology supports 24/7 operations - Infrastructure Communication

Option for vehicle-to-everything-ready systems available - Cameras

External and internal cameras provide 360º all-round visibility for response and situational awareness - LIDAR

Multi-plane LIDAR provides all-round object detection and response within 100 m - Radar

Provides mid and long-range object detection - Human Machine Interface (HMI)

Intuitive HMI for passengers and Vulnerable Road User notifications

Charging System:

The bus is known to be capable of both Plug-in charging and Pantograph charging.

See Also: Autonomous Buses in Singapore

Road trials (Jurong Island)

In June 2019, the ST Engineering STROBO Series 12 Bus (Linkker 12 LF) started undergoing trials on an extended route in Jurong Island between Sakra Region and Jurong Island Checkpoint without passengers.

From around June 2020, public trials would commence, with both the STROBO Series 12 Bus and the Linkker 12+ buses plying the route. The buses will initially travel at a speed of about 20kmh, eventually increasing to 50kmh. During the public trials, a safety driver would be present to monitor the vehicle’s operations if needed, and all passengers would be required to fasten their seat belts while on the bus.

ST Engineering-Linkker Autonomous Electric Bus (Linkker 12+):

In September 2018, the first Linkker autonomous bus, registered as RD3151T, was spotted on test on public roads. The bus is a Linkker 12+ electric city bus, configured in a low-entry layout with three doors.

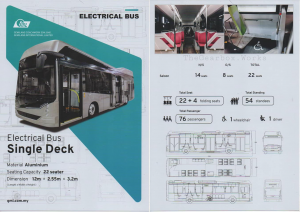

| Basic Technical Specifications | |

| Size | 12.8 m (Length) x 2.55 m (Width) x 3 m (Height) |

| Electric Motor | Danfoss Editron Permanent Magnet Motor (Model TBC) Maximum power 180 kW; Maximum torque of 7.824 Nm at rear axle |

| Battery | Lithium titanate oxide batteries: 63.5kWh. Supplied by Actia (France) Charged via an overhead pantograph with secondary plug-in charging capability |

| Bodywork | Linkker 12+ (Integral bodywork); Low Entry layout Linkker LinkLight lightweight aluminium |

| Seating Capacity | TBC |

| Maximum Operating Speed | Up to 60 km/h |

| Operating Range | 30 – 50 km, depending on operating scenarios |

Similar to the MAN Lion’s City SD 3-door, the raised rear section requires the addition of steps to access the rearmost door.

It is not known if this bus was shipped in completely-built-up (CBU) or assembled locally.

ST Engineering-Linkker Autonomous Electric Bus (Linkker 12 LF):

Main Article: ST Engineering STROBO Series 12 Autonomous Electric Bus

In October 2018, a second Linkker autonomous bus was identified, when the Linkker 12 LF was revealed by ST Engineering at a company event (Singapore Business Night) held at Singapore Expo.

In October 2019, the bus was exhibited at the 26th Intelligent Transport Systems (ITS) World Congress, branded as the STROBO Series 12 Bus and bearing the Research and Development registration plate “RD3165D“.

A more detailed write-up is available at the main article: ST Engineering STROBO Series 12 Autonomous Electric Bus.

Gallery:

External Links & References:

- LTA Inks Agreement with ST Kinetics to Develop and Trial Autonomous Buses – LTA

- Linkker – business from Finnish electric bus competences [PDF]

- LINKKER 12+ Data sheet [PDF]

- Julkinen liikenne sähköistyy – kotimainen Linkker iskee kiinni megatrendiin – op.media

- Shaping Future Mobility – Autonomous Mobility Solutions – ST Engineering

- ST Engineering Steps Up Autonomous Vehicle Capability For Local Deployment and Overseas Rollout – ST Engineering

- ST Engineering launches 12m-long autonomous bus; public trials to start on Jurong Island next year – The Straits Times

Back to Electric Buses in Singapore

Back to Autonomous Buses in Singapore

Back to Bus Models

This Linkker bus was not built by STK. The chassis with a basic frame was built by Linkker in Finland and the rest of the body was designed and manufactured by Gemilang Coachwork International in Malaysia

We know that. ST Engineering is just a dealer and that’s all. The MAN A22s and MAN A95s they sold to LTA were manufactured by Gemilang Coachworks too.