Page 2

Axle, Steering & Hydraulic Systems

On the Enviro500, the steering system is the only use of hydraulics on the vehicle, ever since the use of a hydraulic cooling system was phased out. The small hydraulic fluid reservoir is located within the engine bay.

The steering gear uses the Bosch RB-Servocom 8095 hydraulically powered steering system, linked to the 458 mm, 4-spoke “coach style” steering wheel with a centre and stalk horn push. The steering column is fully adjustable in reach and rake, and interlocked with handbrake for added safety.

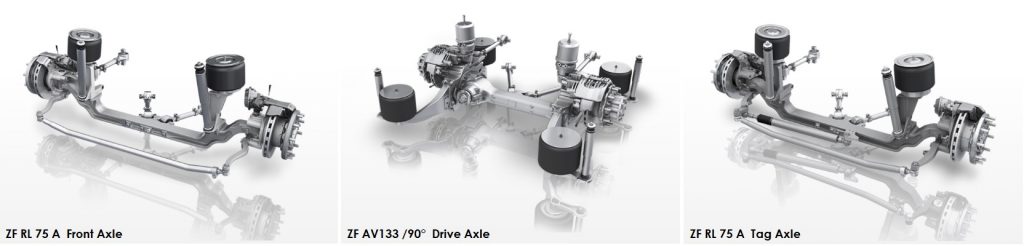

Axles are supplied by ZF, which also supplied the transmission gear. All axles used are portal axles (or drop axles) which have the axle located below the centre position of the wheel. This is done to accommodate the low floor layout of the bus cabin.

- Front Axle: ZF RL75 dropped centre cast beam axle with disc brakes. 7,500kg design capacity

- Drive Axle: ZF AV133 /90° portal axle with double tyres and choice of gear ratios. 5.13:1, 5.73:1 and 6.19:1. 12,000kg design capacity

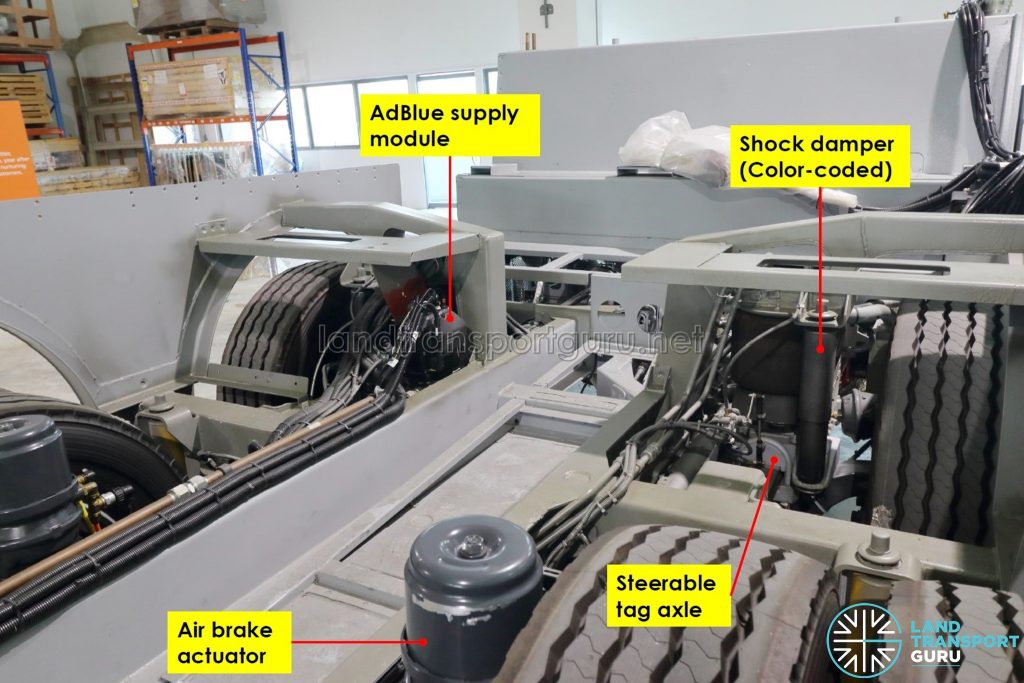

- Tag Axle: ZF RL75 dropped centre cast beam axle with disc brakes. 7,500kg design capacity with ZF Servocom RAS Steering System

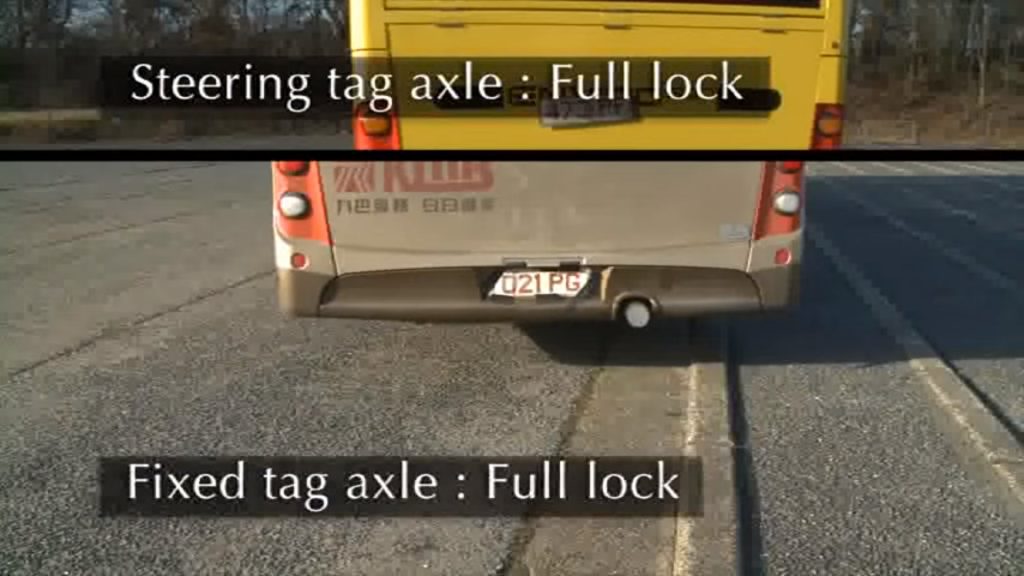

On this Enviro500, the customer New World First Bus had opted for the ZF Servocom active rear axle steering (RAS) system, also known as a steerable tag axle. When in use, the rearmost axle turns in the opposite direction of the front axle. This improves the manoeuvrability of the bus by reducing its steering radius and reduces tyre wear on the tag axle.

In Hong Kong, RAS systems are gaining in popularity with local bus operators Citybus and New World First Bus since their introduction several years ago, with both 12-metre and 12.8-metre buses receiving the option. Notably, in 2018, Kowloon Motor Bus disabled RAS across its fleet.

In Singapore, the tag axle on Enviro500 buses are not fitted with RAS capabilities but can be retrofitted as an option. The current MAN A95 – Lion’s City DD (3-Door) Concept Bus (SG5999Z) is presently also equipped with RAS.

However, RAS is not without its disadvantages; when applying the maximum steering angle from stationary (aka full lock), the rear outswing increases by “about 9 or 10 inches” according to Alexander Dennis, which could lead to sideswipe incidents. As a result, operator training is necessary to mitigate this risk.

For the tyres, New World First Bus has opted for steel-rimed tyres. For buses in Singapore, aluminium alloy rims are usually preferred, with Alcoa rims being the most common.

- [1] ZF ServoCom [PDF]

- [2] ZF Product Overview – Axle & Transmission Systems for Buses & Coaches [PDF]

- [3] Enviro 500 Tag Axle Demo – YouTube

Electrical Systems

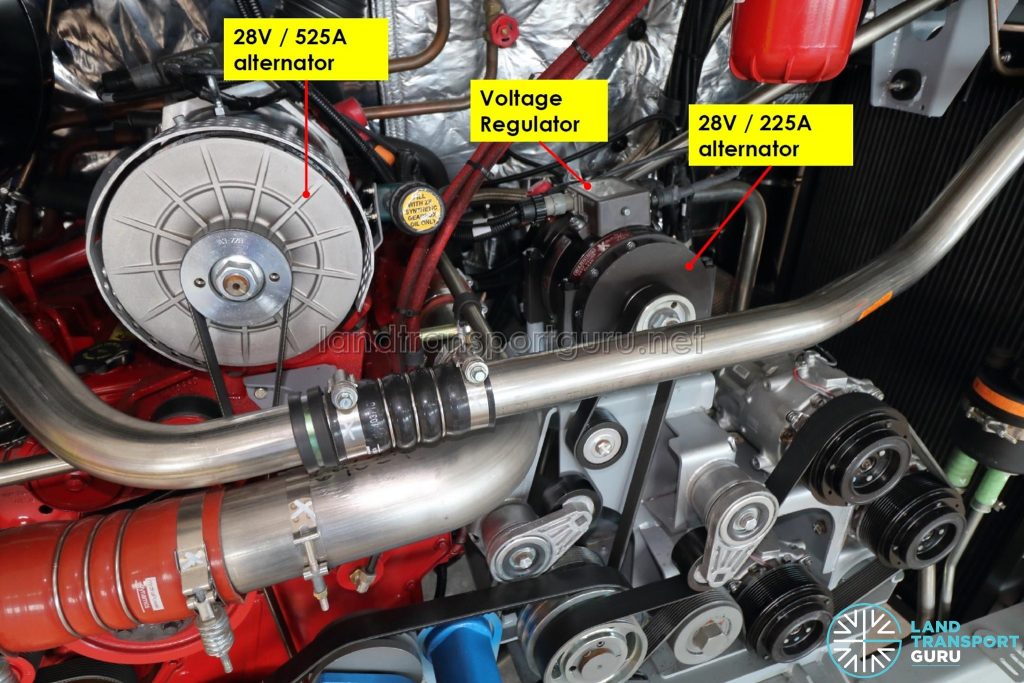

The Enviro500 has 1x Niehoff C530 (28V / 225A) alternator and 1x C803D (28V / 525A) alternator for electricity generation, both belt-driven and mounted within the engine compartment. They are supplied by C.E. Niehoff & Co. from the US. Each generator produces an output voltage of 28 V.

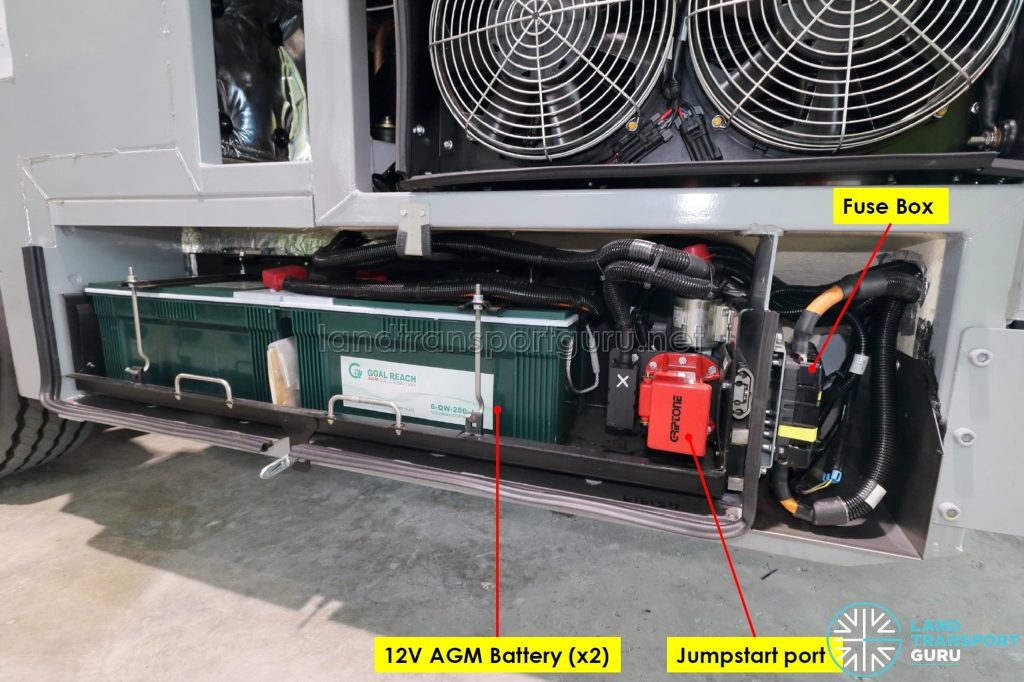

For the batteries, the bus uses 2x Goal Reach 255Ah batteries mounted in the battery compartment at the left rear of the bus, delivering the 24V DC vehicle power supply which powers all onboard electrical systems on the bus (Model no.: 6-QW-200-J). These AGM (absorbent glass mat) batteries are made by Shen Zhen Goal Reach from China, are maintenance-free, and offer longer service life and better discharging characteristics as compared to traditional lead-acid batteries.

- [1] C803D – 28 Volt / 525 Amp Alternator – C.E. Niehoff

- [2] C530 – 28 Volt / 225 Amp Alternator – C.E. Niehoff

- [3] 6-QW-200-J – Shen Zhen Goal Reach

Cooling Package

The radiator is mounted on the right of the engine bay. To cool the engine, coolant fluid is passed through the engine block, where it absorbs heat from the engine. The hot coolant passes through the radiator, which transfers the heat to the ambient air. The coolant is thus cooled and routed back into the engine.

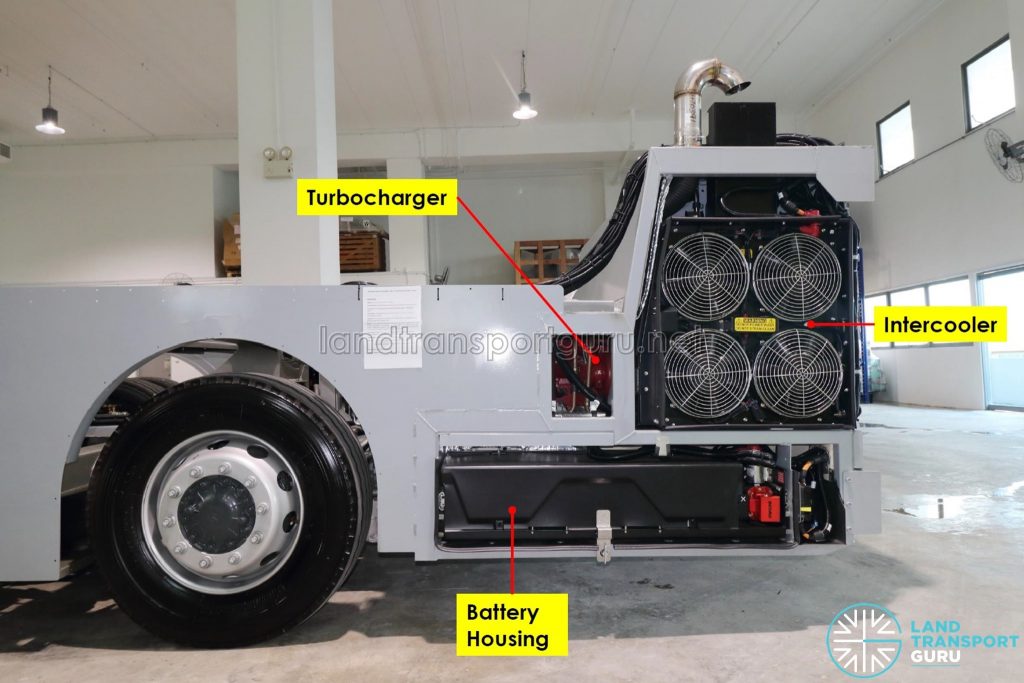

The intercooler is mounted on the left of the engine bay, and it is used to cool down air within the intake manifold before it enters the combustion chambers of the engine. When intake air passes through the turbocharger, it is quickly compressed and thus increases in temperature. Cooling down this air before it enters the engine is advantageous as it improves the combustion efficiency of the engine.

In the case of an air-to-liquid intercooler (such as one installed on the Enviro500), heat from the intake air is first transferred to water, which transfers the heat to the ambient air. Fluid circulation is driven by a circulation pump at the lower left of the engine. Further reading is recommended for a deeper technical understanding of both the radiator and the intercooler.

Miscellaneous

For buses built to Hong Kong specifications, an emergency engine cut-off switch is required to be mounted on the exterior of the bus. Such a provision has been made on the chassis, with an additional cutoff button located near the right radiator.

In addition, three belt-driven air-con compressors are installed on the right side of the engine bay. Coolant pipes to and from the compressor, as well as the remaining components of the air-conditioning system, will be installed by the bodybuilder.

Photo Gallery:

Special thanks to Alexander Dennis for the invitation and for making this article possible.

Specifications:

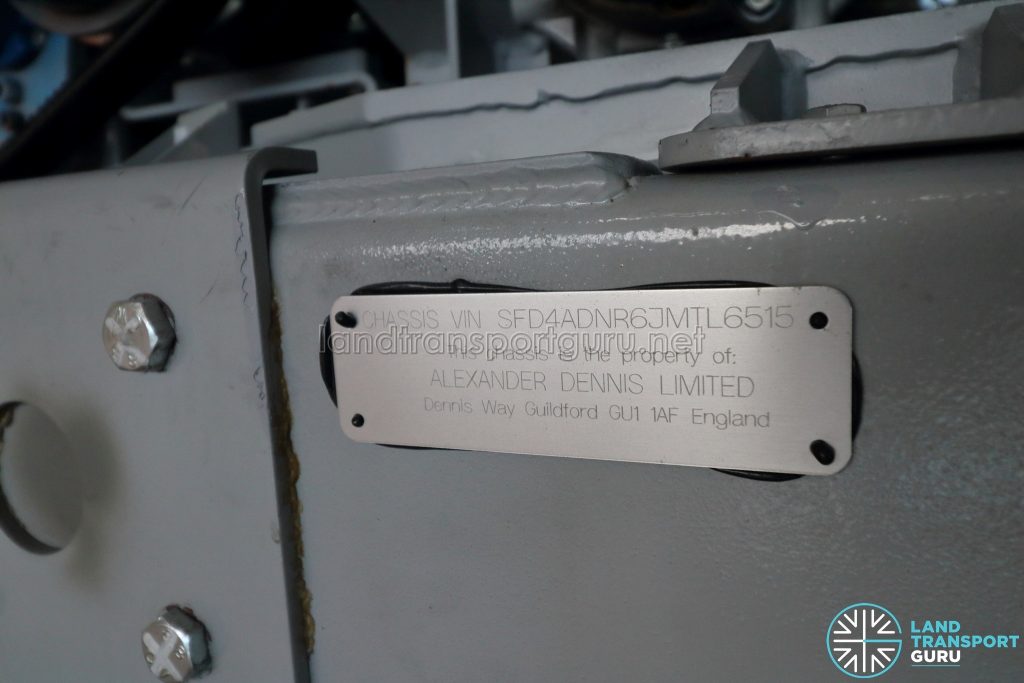

- Chassis: Alexander Dennis Enviro500 MMC 12m for New World First Bus

- Engine: Cummins L9E6C340B

- Emission Standard: Euro 6 (SCR)

- Transmission: ZF EcoLife 6AP1700B

- Rear Axle Steering

技術資訊:

- 底盤: 亞歷山大丹尼士 Enviro500 MMC 12米 (新巴)

- 引擎: 康明斯 L9E6C340B

- 排放標準: 歐盟六期 (選擇性催化還原系統)

- 波箱: ZF EcoLife 6AP1700B

- 尾軸輔助轉向

External Links & References:

- Alexander Dennis opens new Asia Pacific facility in Singapore – Alexander Dennis

- Alexander Dennis Main Website

Back to Bus Models

Previous Page (Page 1):

- Introduction & Background

- Engine & Transmission Components

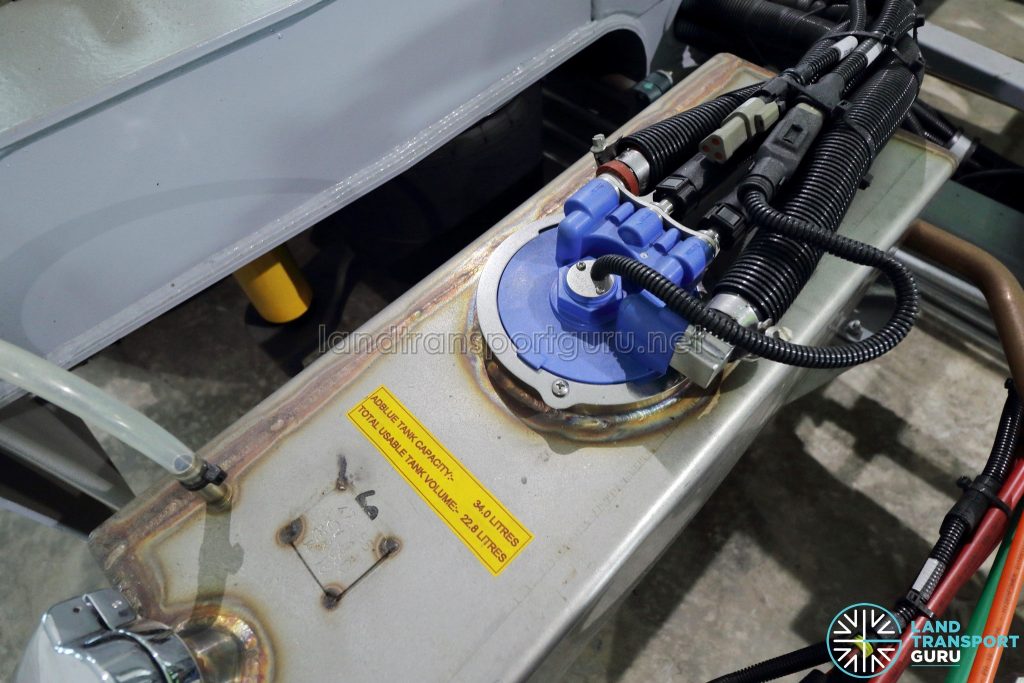

- Fuel & AdBlue Systems

- Pneumatic Systems & Peripherals