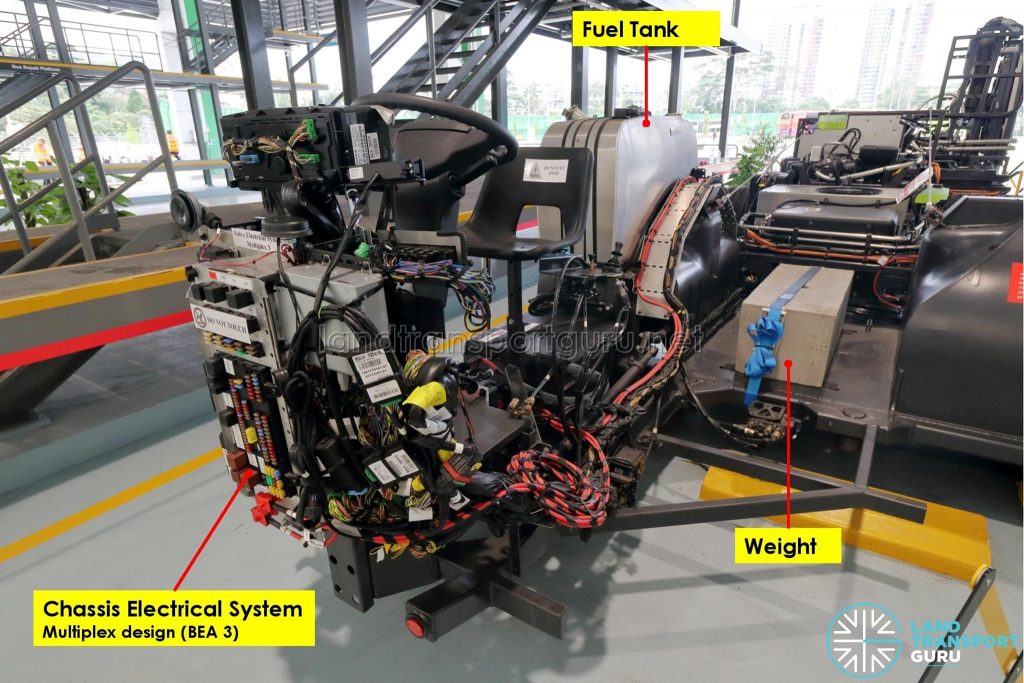

Electrical Systems

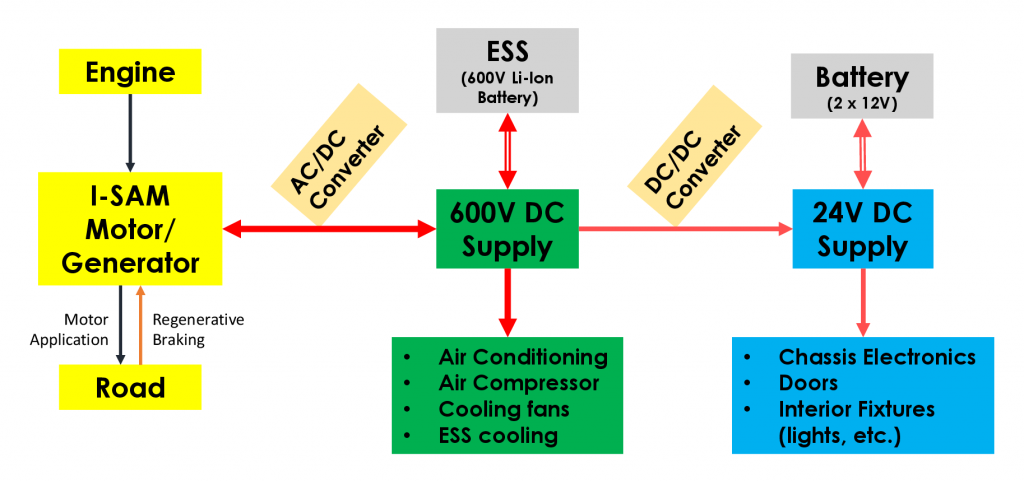

The Volvo B5LH has two separate electrical systems, namely a 600V DC and a 24V DC power supply.

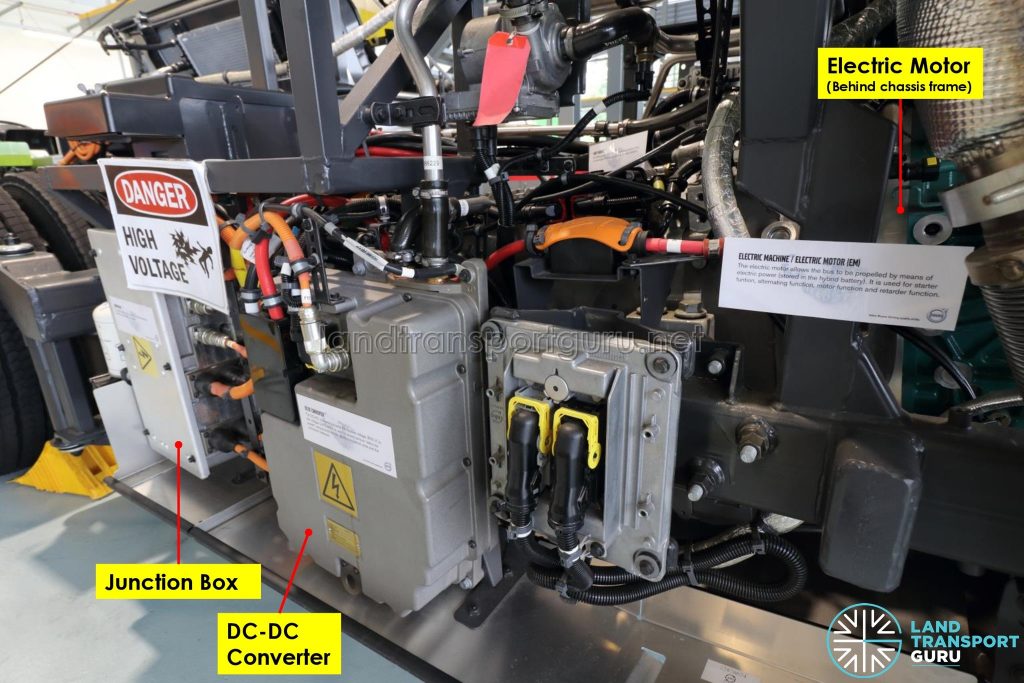

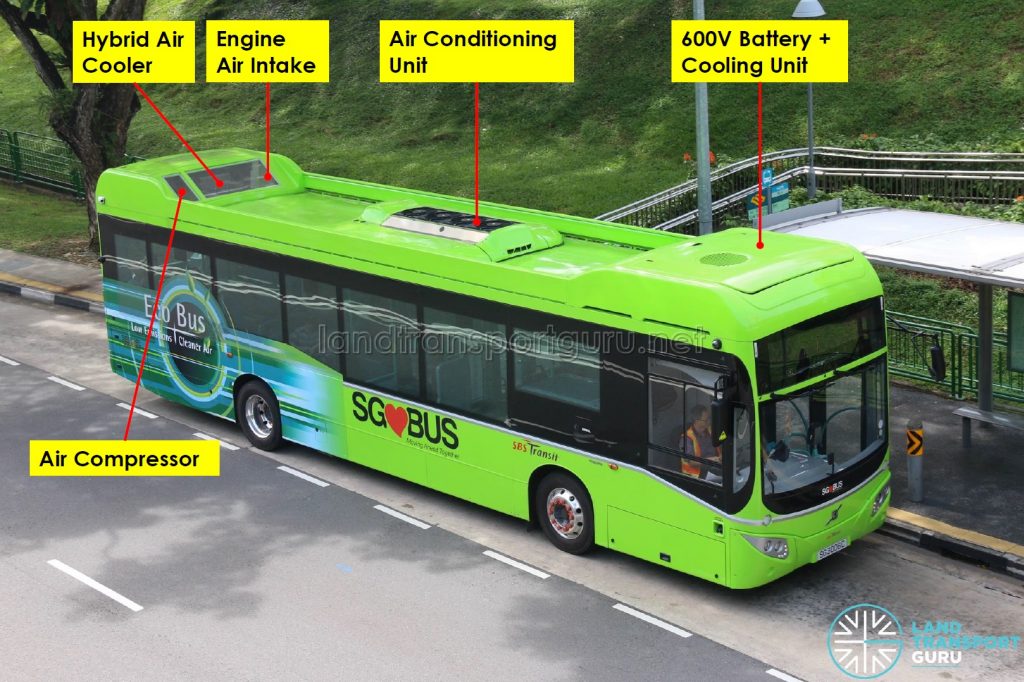

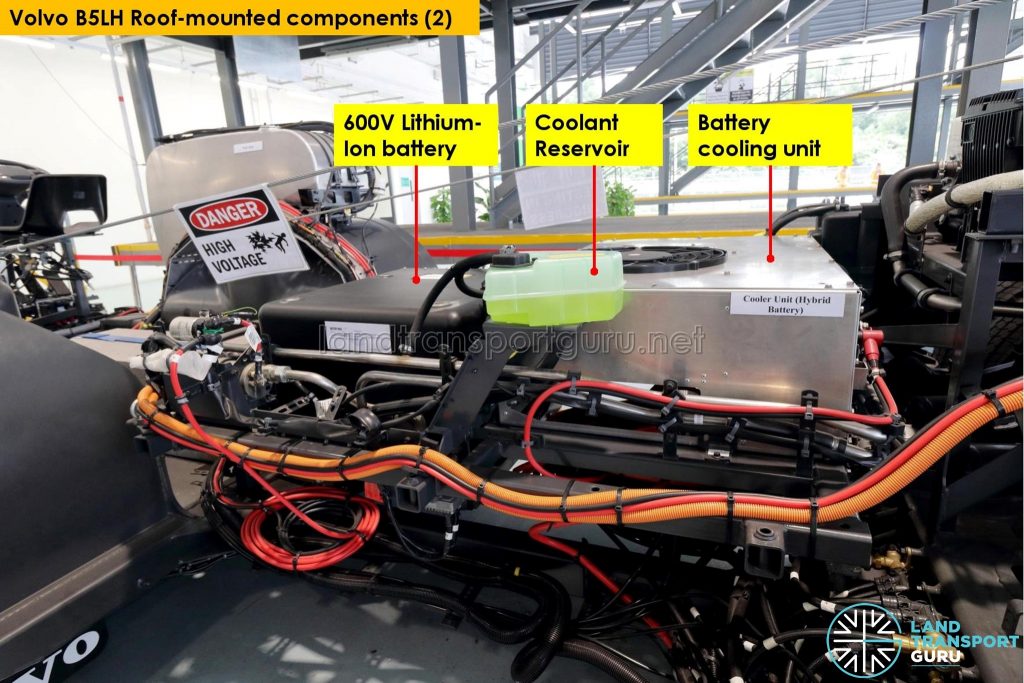

Firstly, the high-voltage 600V DC supply powers the traction motors, air compressor and air-conditioning. The energy store is a 600V 4.8 kWh lithium-ion battery mounted on the roof of the bus, with its own independent cooling system to maintain an optimal working temperature for the battery. Energy in this system is recharged by the I-SAM traction motor working as a generator. On the Volvo 7900 Electric Hybrid, the energy store is boosted to 19kWh as the bus primarily operates in electric mode.

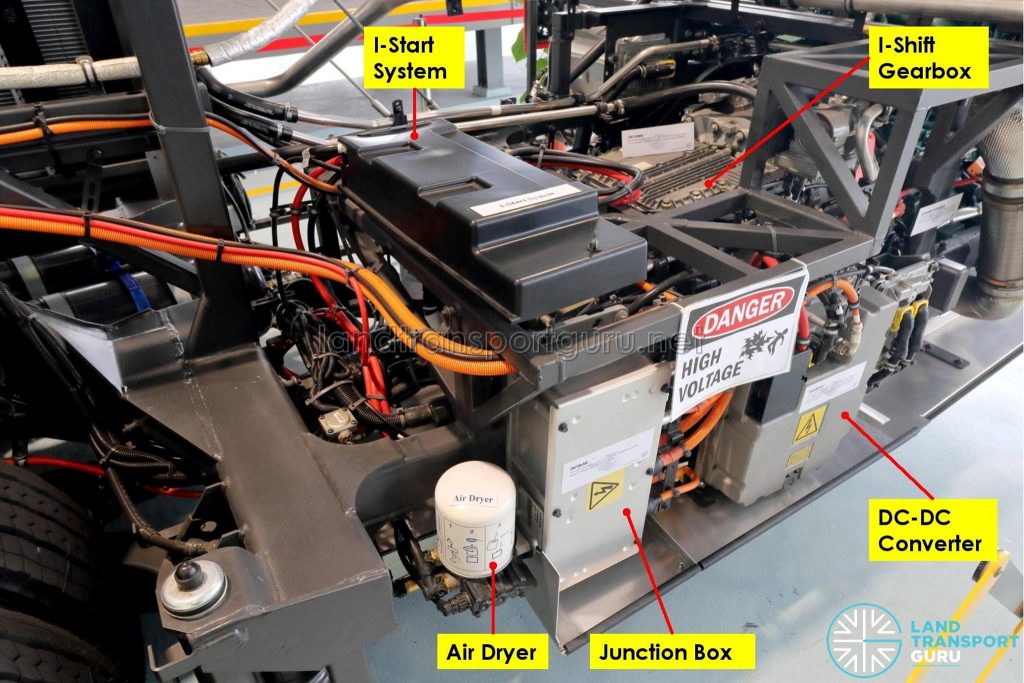

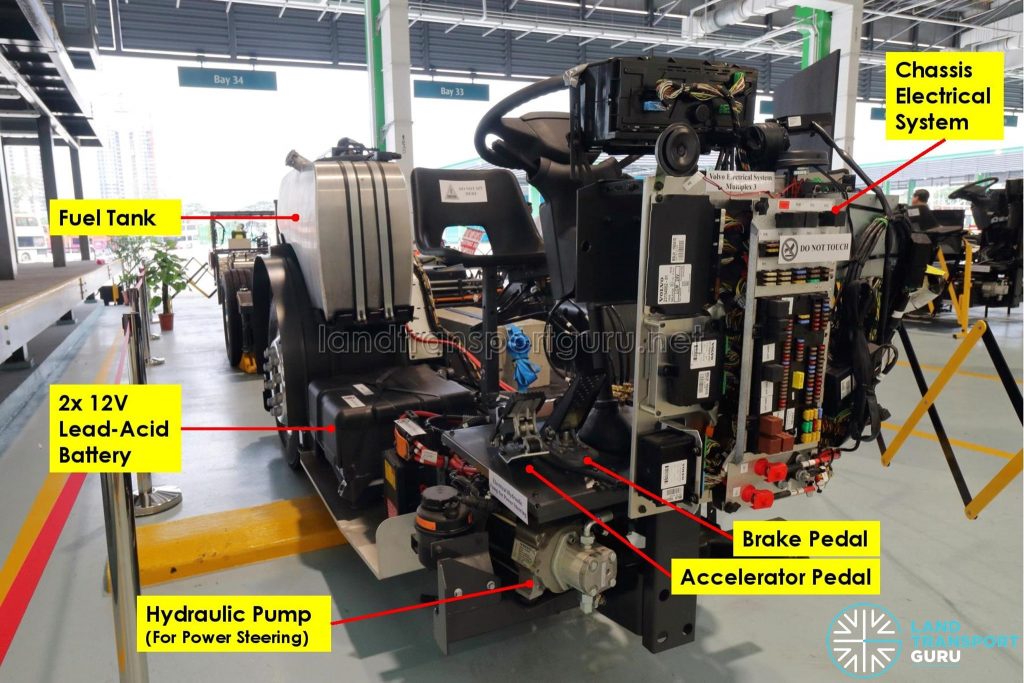

The conventional 24V DC supply powers the bus’s onboard electronic systems, equipment such as interior lighting and doors, and other peripheral systems. The energy store uses conventional 2x 12V 225Ah lead-acid battery mounted on the right side, ahead of the front wheel. Energy in this system is recharged by the I-SAM traction motor through a DC/DC converter (which in this case, is similar to the alternator on a regular diesel bus). On the Volvo 7900 Electric Hybrid, the energy store is boosted to 19kWh as the bus primarily operates in electric mode.

The bus uses Volvo’s 3rd generation bus electrical architecture (BEA3), offering data transmission, bus systems control, monitoring and coordination of all devices installed on the bus, including electronic control of the engine management system, transmission and suspension. Its multiplexed electronics system supports preventive maintenance and is supported by software diagnostics tools for testing, calibrating and reprogramming.

The doors, air conditioning, air compressor, cooling fans and power steering are examples of features that are electrically powered in a Volvo B5LH. This not only helps save fuel, it also means the bus is fully operational even when the diesel engine is switched off.

Pneumatic Systems & Peripherals

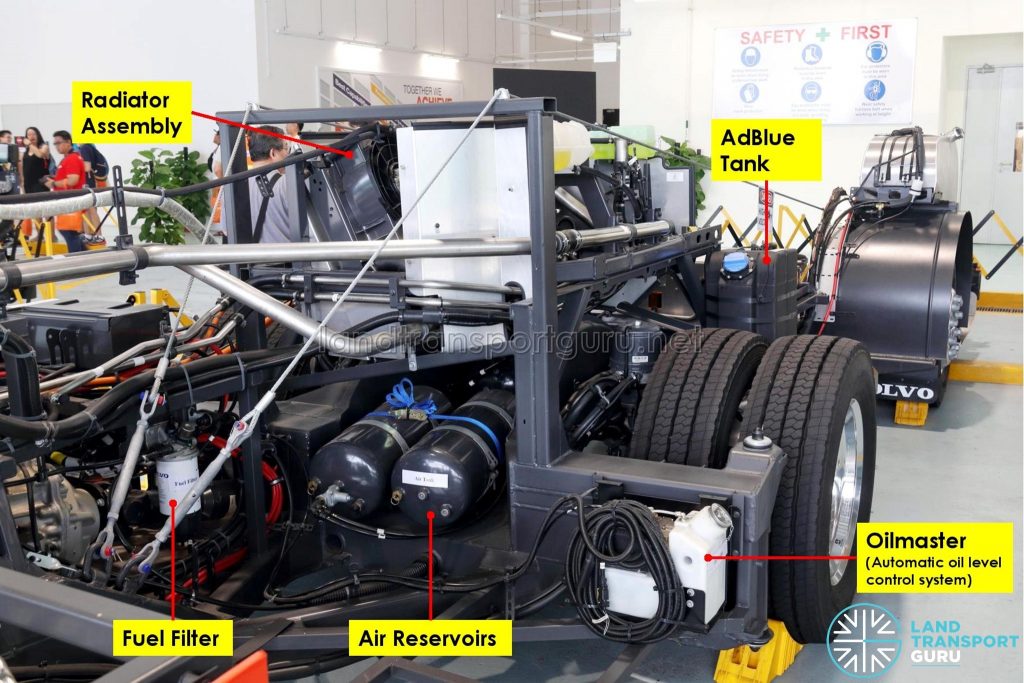

On most buses, compressed air (pneumatic) systems are used to operate several systems, such as the service brakes, parking brake, suspension, and doors, and the Volvo B5LH is no different. The compressed air system itself comprises many complex sub-components.

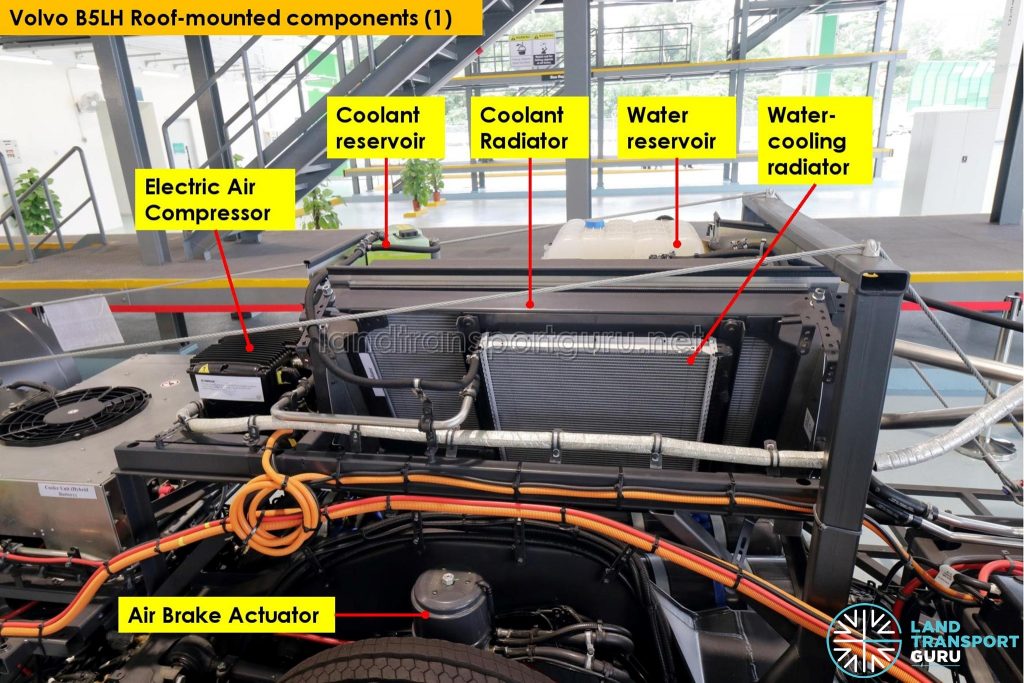

Unlike conventional diesel buses with engine belt-driven air compressors, the Volvo B5LH uses a rotary-type air compressor driven by an electric motor, which is independent of the diesel engine. The compressor is mounted on the rear portion of the bus roof, drawing draws from the high-voltage 600V DC supply of the bus. After compression and cooling, air is channeled to the air dryer for filtration to remove moistures and impurities. The air dryer is located on the left side of the bus, just behind the rear wheel, and ensures that clean and dry air is supplied to the pneumatic systems.

Buses are typically designed with independent pneumatic systems for the service brake, parking brake, and suspension systems. Within each pneumatic system, compressed air is stored in a supply reservoir (which is mounted above the rear axle on the transport chassis but likely relocated to the rear right portion in the completed bus, where the third door would have been for LHD markets).

Braking systems

The Volvo B5LH uses Volvo Electronic Braking System (EBS5), which includes ABS and ASR functions for anti-lock braking and traction control respectively.

Suspension system

The Volvo B5LH uses an electronically controlled air suspension system with kneeling function.

Roof-Mounted Components

The chassis exhibited at the carnival was a transport chassis, where components are arranged for shipment rather than their actual position on the completed bus. Roof-mounted components are placed on the floor of the chassis.

Energy Storage System

Mounted on the very front of the bus, the energy store is a 600V 4.8 kWh lithium-ion battery with its own independent cooling system to maintain an optimal working temperature for the battery. Energy in this system is recharged by the I-SAM traction motor working as a generator.

Air Conditioning

The Volvo B5LH uses the Valeo REVO-E roof-mounted air-conditioning unit, optimized for hybrid and electric buses. Unlike traditional bus air-conditioning systems where the compressors are engine-driven, the REVO-E has electrically-driven compressors integrated into the roof unit, without the need for refrigerant piping. It is capable of operating on both 600V DC and 24V DC supply. The air-conditioning unit was not exhibited alongside the chassis.

Cooling Package

The radiator is mounted on the rear roof section. To cool the engine, coolant fluid is passed through the engine block, where it absorbs heat from the engine. The hot coolant passes through the radiator, which transfers the heat to the ambient air. The coolant is thus cooled and routed back into the engine. Water is also cooled within a separate part of the radiator – the I-SAM electric motor/generator is water-cooled (The energy storage system is independently cooled).

Another part of the cooling package is the intercooler is mounted on the left of the engine bay, and it is used to cool down air within the intake manifold before it enters the combustion chambers of the engine (explained under Engine section). When intake air passes through the turbocharger, it is quickly compressed and thus increases in temperature. Cooling down this air before it enters the engine is advantageous as it improves the combustion efficiency of the engine. Further reading is recommended for a deeper technical understanding of both the radiator and the intercooler.

Electric Air Compressor

Forming part of the Pneumatic System, the electric air compressor is mounted on the rear roof of the bus.

Miscellaneous

Axle, Steering & Hydraulic Systems

On the Volvo B5LH, the steering system utilizes hydraulics, with the electrically driven steering pump is located under the driver’s cab. The steering wheel position is adjustable for height and rake.

Photo Gallery:

Addendum

This is Land Transport Guru’s first foray into covering a bus chassis from a technical standpoint, which we have put together only through publically available documents. Land Transport Guru cannot vouch for the full accuracy of the points presented and we welcome viewers to point out any errors.

Let us know if you enjoyed the article and would like to see more of such content.

External Links & References:

- —

Back to Volvo B5LH

Back to Bus Models

Previous Page (Page 2):

- Engine & Transmission Components

- Emissions Control

- Hybrid Drivetrain