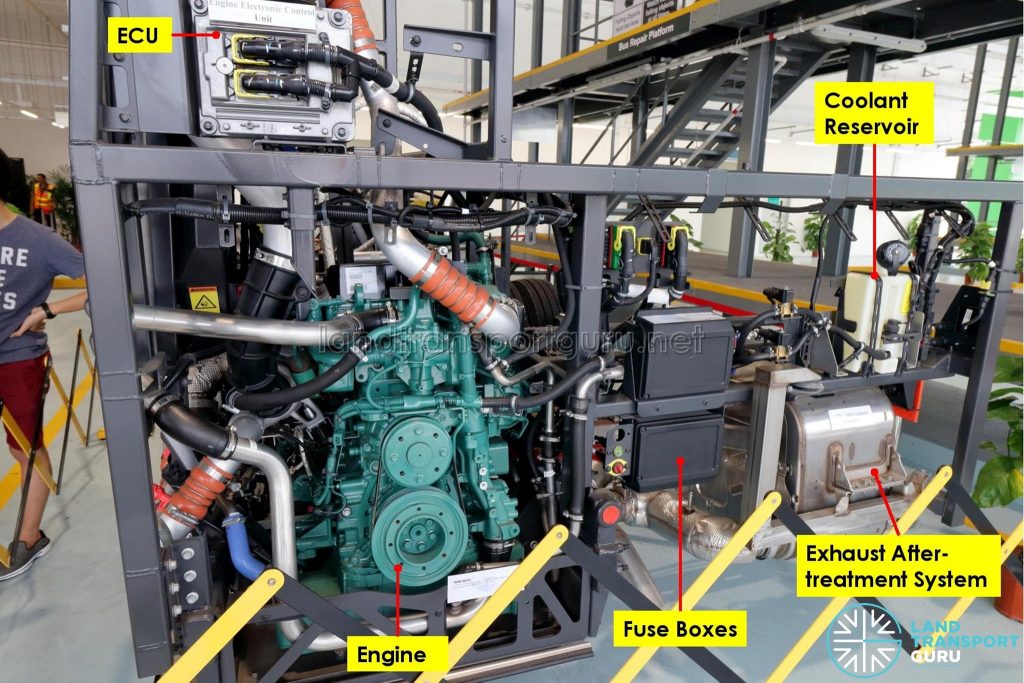

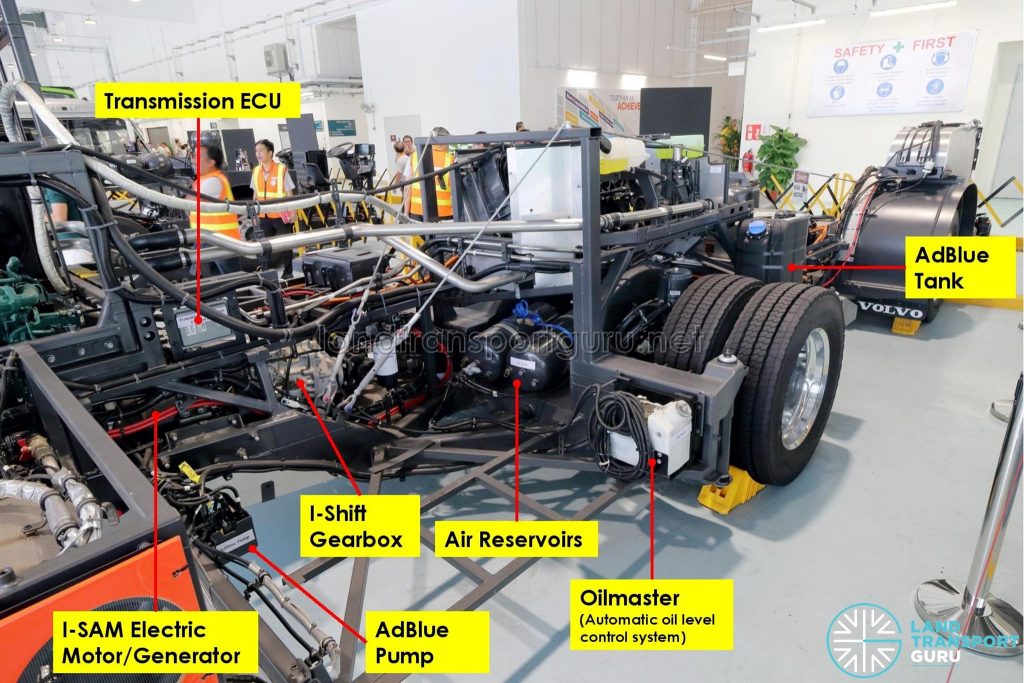

Engine & Transmission Components

The parallel hybrid system comprises both a diesel engine and an electric motor. We will discuss the diesel engine first.

| Engine | Volvo D5K240 (Euro 6) Inline 4-cylinder turbocharged & intercooled, 5132cc displacement Power/Torque rating of 240hp (177 kW) @ 2200 rpm | 918Nm @ 1200-1600 rpm |

| Emission Standard | Euro VI-compliant Engine incorporates Exhaust Gas Recirculation (EGR) Exhaust Aftertreatment System Modular system combines a muffler, Diesel Oxidation Catalyst (DOC)/Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) chamber. Meets the latest Euro VI emission standard and requires diesel exhaust fluids (AdBlue). |

| Transmission | Volvo AT2412E I-Shift gearbox Twelve-speed automated transmission |

The Euro 6 Volvo B5LH is fitted with a Volvo D5K240 powerplant. The inline, four-cylinder, four-stroke engine has a displacement of 5132 cubic centimetres, and delivers a power rating of 240 hp (177 kW) @ 2200 rpm, and torque rating of 918Nm @ 1200-1600 rpm with common rail injection. While low in power in absolute terms, the hybrid driveline compensates with the electric motors for propulsion at low speeds.

An upgrade for the Euro 6 engine such as the Volvo D5K is the use of a Variable Geometry Turbocharger (VGT), which offers turbo performance and driveability improvements across the entire range of engine speeds while also acting as an exhaust brake. In contrast, the Euro 5/EEV Volvo D5F engine used on pre-2013 production Volvo B5LH buses have a wastegated turbocharger with a lower rpm operating range. As such, the Euro 6 Volvo B5LH bus can stay within the economy rev band easily with minimal gear changing. Volvo touts its D5K engine on its drivability, efficient combustion, low noise levels and long service life.

Volvo offers emissions control via its Exhaust Aftertreatment System (EATS), which is explained in a later section.

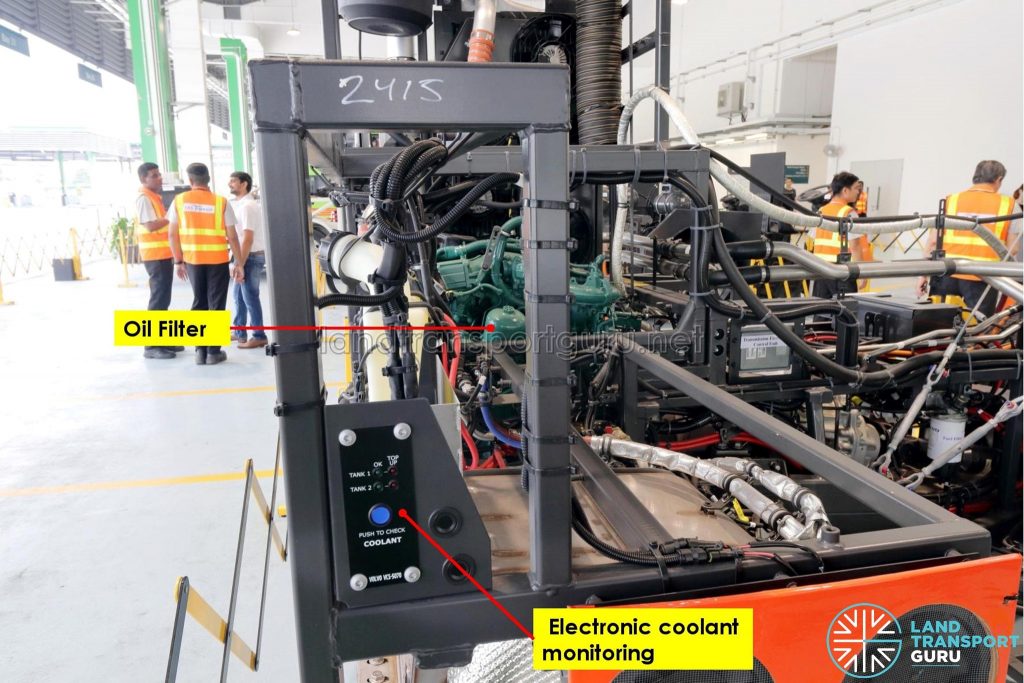

The Volvo B5LH is delivered with the Oilmaster automatic oil level control system as standard, supplied by Dutch company Groeneveld (mounted behind the right rear wheel). It ensures that the oil in the engine is always at the optimal level by monitoring oil levels in the engine sump and replenishing where necessary, eliminating the need to manually check oil levels at regular intervals. It is understood that the Volvo B5LH is the first batch of new buses in Singapore to have the Oilmaster implemented across all buses as standard.

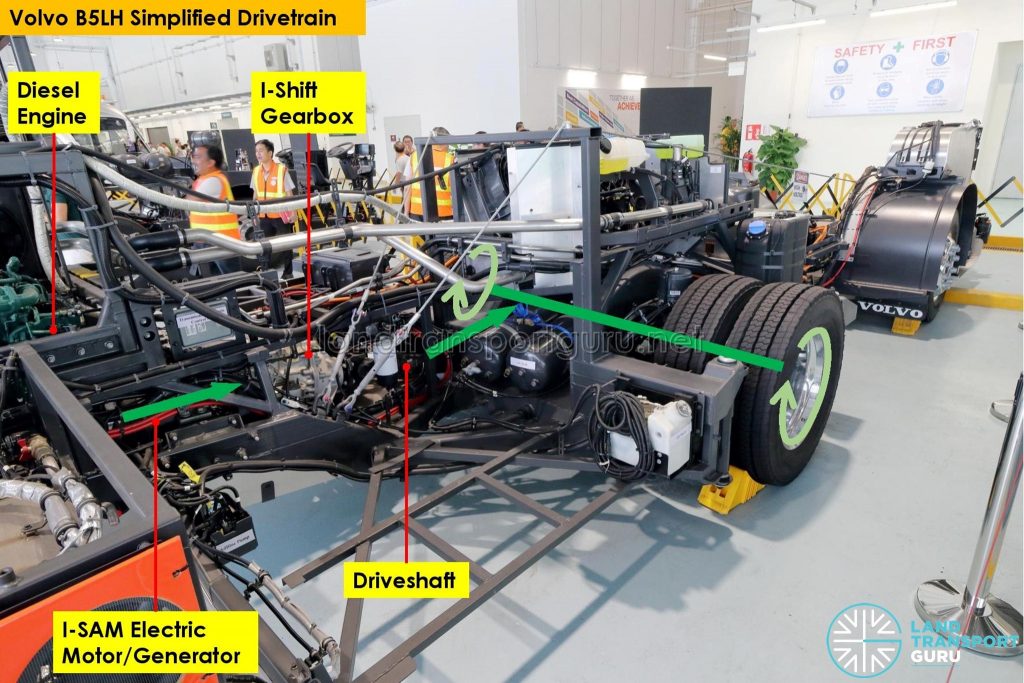

For the transmission, the bus is fitted with the Volvo AT2412E I-Shift automated manual transmission originally developed for trucks but adapted for hybrid vehicles. The bus executes software-controlled gear changes automatically, accelerating in ‘steps’ very similar to a manual transmission. It offers twelve gears in forward and four in reverse. Retarder effect is provided by the electric motor (explained below).

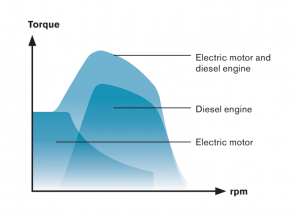

The transmission is unique in being able to combine the torque from the electric motor and diesel engine for smooth operation. During gear-shifting, the transmission program uses the electric motor to synchronise input and output shafts to speed up and optimise the comfort of the gear-shift. The electric motor and the Energy Storage System (ESS) are also used to ensure that torque interruptions during gear-shifting are minimised.

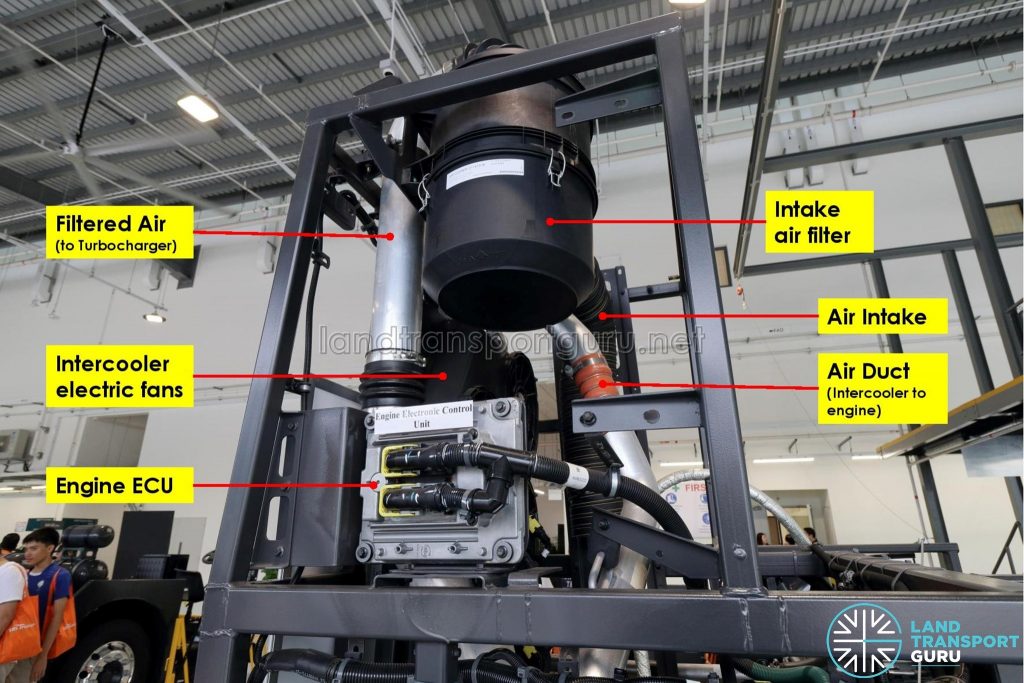

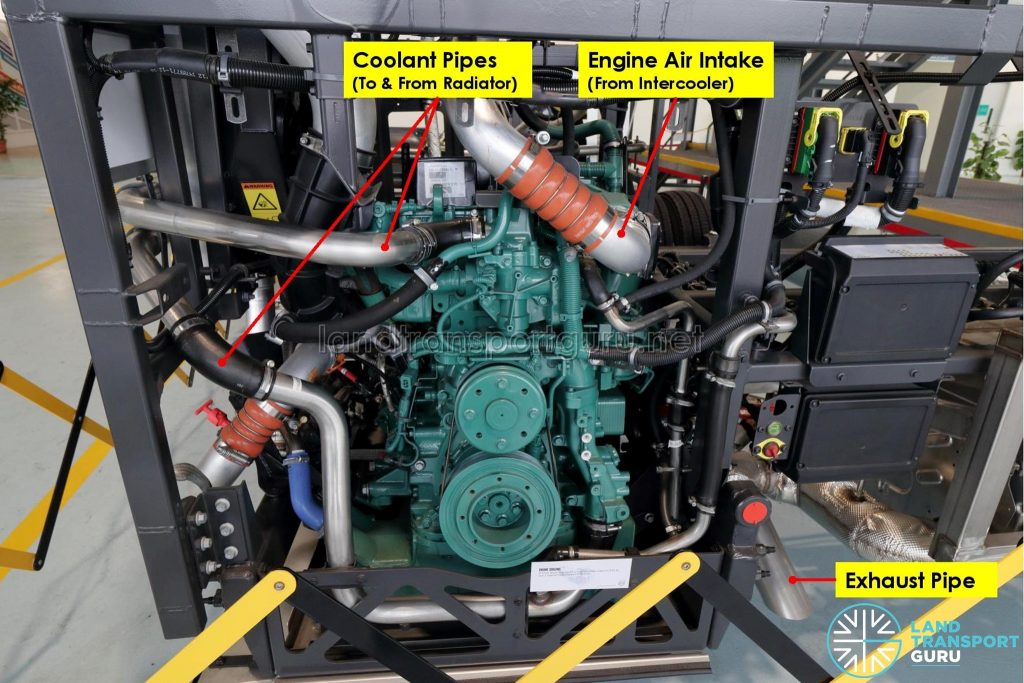

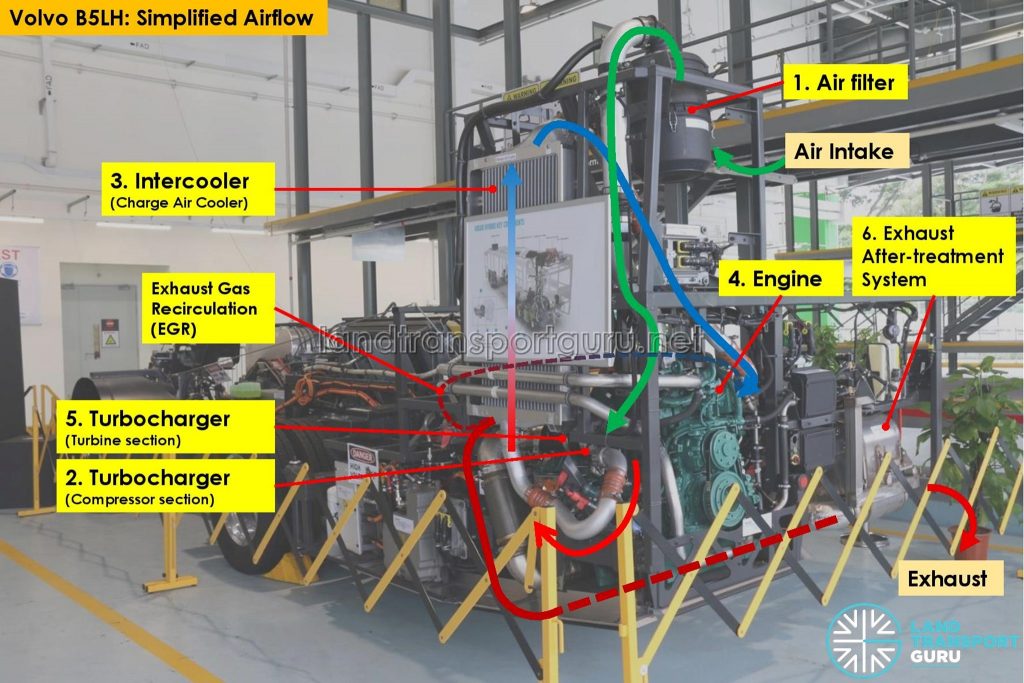

Simplified Airflow

The air intake of the Volvo B5LH is on the roof, and the air first passes through an air filter to remove large airborne particles. It then enters the turbocharger where the clean air is quickly compressed to supply more air to the engine, but the air is heated up in the process. Next, the air passes through an intercooler which cools down the air before feeding it into the combustion engine, improving combustion efficiency.

After passing through the combustion process in the engine, a portion of the exhaust gas is directed back into the engine’s intake manifold and mixed with air from the intercooler as part of the EGR process. The remaining exhaust gas is fed into the Exhaust Aftertreatment System, where a combination of SCR and particulate filters scrub the exhaust before it is ejected from the vehicle.

- [1] D5K240 Fact Sheet – Volvo Trucks [PDF]

- [2] Volvo Electric Hybrid Driveline – Volvo Buses [PDF]

- [3] Volvo Hybrid Bus – Volvo Buses India

- [4] Volvo 7900 Hybrid Specifications – Volvo Buses UK

- [5] Tailoring your Volvo FL [PDF]

- [6] Oilmaster – Groeneveld Lubrication Solutions

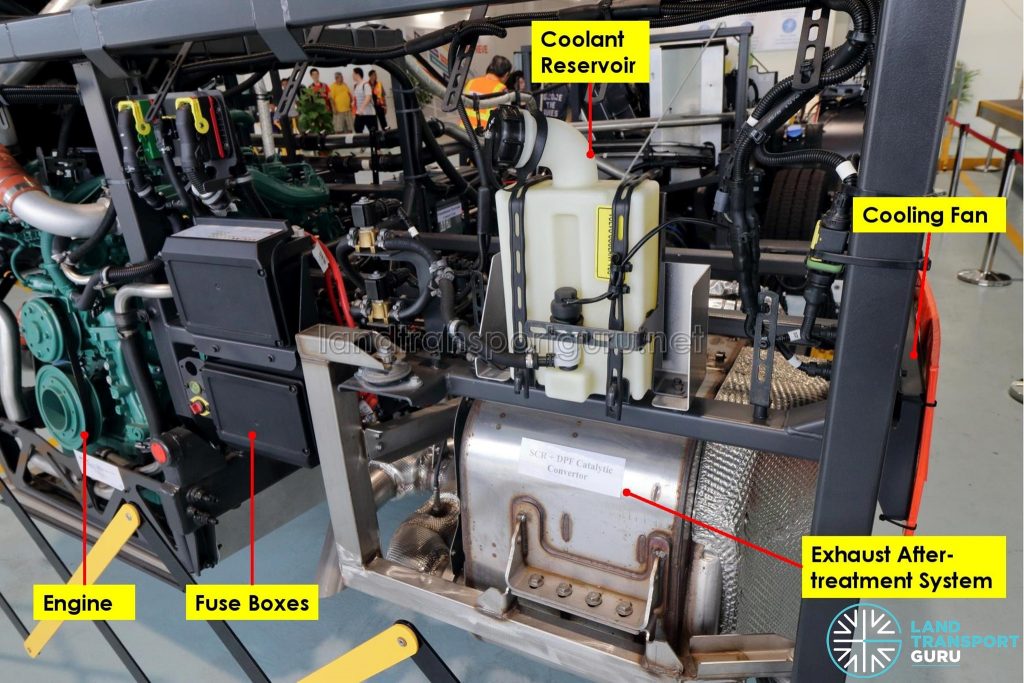

Emissions Control

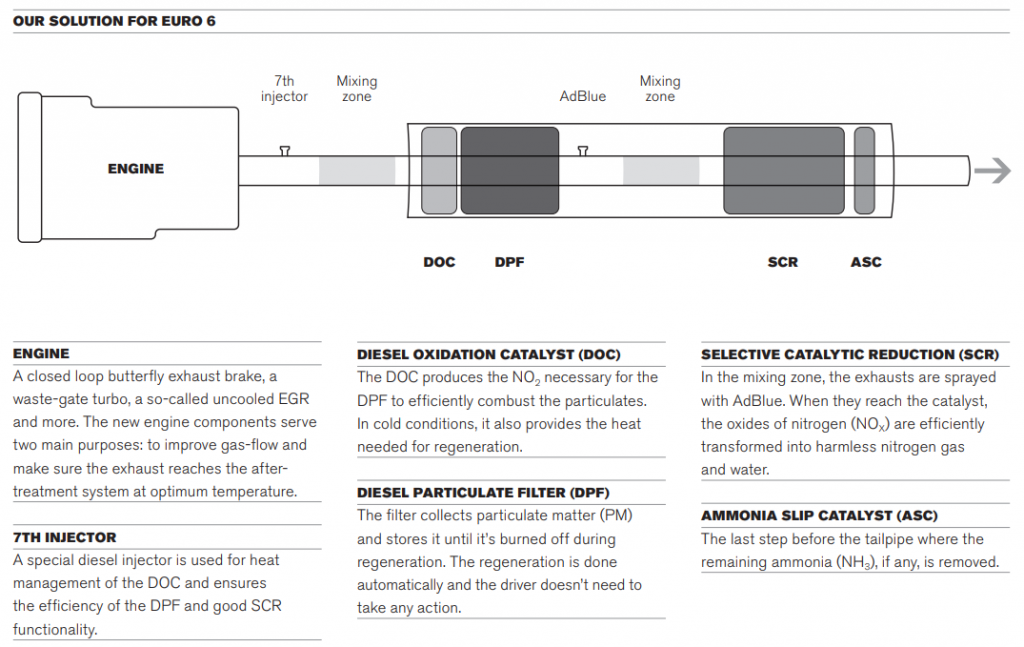

For emissions control, the bus utilizes Exhaust Gas Recirculation (EGR) in the engine and a combination of Selective Catalytic Reduction (SCR), Diesel Oxidation Catalyst (DOC) and Diesel Particulate Filter (DPF) within an integrated exhaust aftertreatment module, called the Exhaust Aftertreatment System (EATS). It is compliant with the Euro 6 emission standard adopted in Singapore for all vehicles registered after 1 January 2018.

The Volvo D5K engine uses Exhaust Gas Recirculation (EGR) as the first step in meeting emission requirements. In simple terms, EGR is a nitrogen oxide (NOx) emissions reduction technique that involves recirculating a portion of the exhaust gases (which is low in oxygen content) back to the engine cylinders. Doing so deliberately reduces the oxygen in the engine’s intake air, thus lowering the combustion temperatures in the engine and reducing NOx formation (High combustion temperatures promote NOx formation). However, EGR leads to lower combustion efficiency, so there is a trade-off between engine performance and emissions.

For exhaust aftertreatment, the Volvo B5LH uses a combination of a Selective Catalytic Reduction (SCR) process, Diesel Oxidation Catalyst (DOC) and Diesel Particulate Filter (DPF) within an integrated exhaust aftertreatment module, called the Exhaust Aftertreatment System (EATS). In particular, Selective Catalytic Reduction (SCR) is a chemical process to further reduce nitrogen oxide (NOx) emissions, converting them into atmospheric nitrogen and water vapour through using diesel exhaust fluids (such as AdBlue) as a catalyst. AdBlue is a 32.5% high-purity urea solution diluted in deionized water, and is injected upstream of the SCR catalyst.

The EATS system on the Volvo B5LH uses the same operating principles as outlined in the above diagram but folded into a compacted module. Do check out the Selective Catalytic Reduction (SCR) article for more details about the SCR process.

AdBlue used on the Volvo B5LH is stored in a small tank at the right side of the bus, just ahead of the rear axle. The supply module (AdBlue pump) can be seen next to the EATS system, but will be concealed by bodywork panels after bodywork assembly. The unit pumps AdBlue fluid from the tank and pressurizes it for injection into the EATS system. [Image Link]

- [1] AdBlue® – Yara

- [2] Volvo Trucks to Now Offer One-Box Exhaust Aftertreatment System – OEM Off-Highway

- [3] Euro 6 After Treatment – Thinking inside the Box – Commercial Motor Archive

Hybrid Drivetrain

Further reading: Hybrid Buses in Singapore

The Volvo B5LH is a parallel hybrid bus with both diesel and electric power, and both powerplants can operate independently of one another. In normal circumstances, the electric motor is used when moving off from a standstill and for accelerating to speeds of up to about 20 km/h (or up till the first gear change, whichever comes first), which promotes considerable fuel savings. At higher speeds, the diesel engine takes over propulsion of the bus, and at the same time, charges the electric motor’s batteries.

The hybrid bus is ideal for urban operations. The electric motor serves both as a propulsion motor and as a generator. When the brakes are applied, the propulsion motor acts as a generator, slowing down the bus while recharging the batteries in a process called regenerative braking – harnessing energy that would otherwise simply be wasted in the form of heat in the braking system. This makes hybrid technology therefore ideal for urban bus routes, which are characterized by repeated stops and starts, and frequent acceleration and braking. However, dynamic braking does not fully supplement friction braking, which acts immediately and is far less effective at lower speeds. Therefore, the bus is still equipped with disc brakes, and computer-controlled brake blending combines both forms of braking to maximize energy recovery while still being responsive to the driver’s brake pedal input.

Owing to its considerable torque, the electric motor offers good performance in the low-speed sector and supplements the diesel engine’s superior torque at higher speeds. The electric motor produces maximum torque right from start, which results in excellent acceleration and driveability. An automatic engine start-stop feature switches off the diesel engine automatically when the bus is stationary.

Hybrid System & Motor:

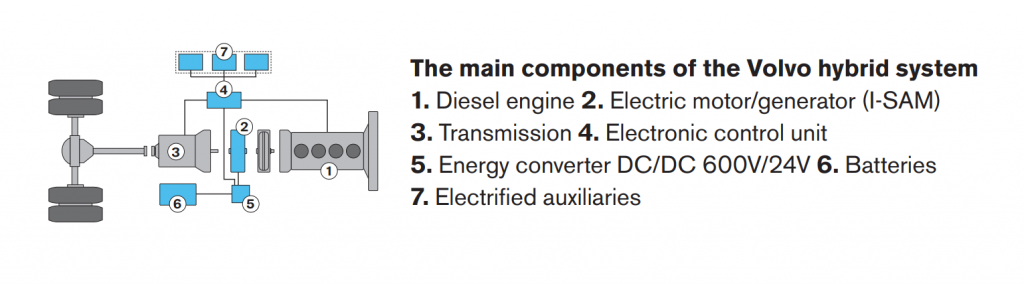

The Volvo Hybrid Driveline on the Volvo B5LH comprises four main components: the Euro VI diesel engine, the I-SAM traction motor, the I-Shift automated gearbox and the energy storage system. The primary energy store is a lithium-ion battery mounted on the roof. The diesel engine and transmission have been explained in the above sections.

The Integrated Starter Alternator Motor (or I-SAM) is a 600V AC permanent magnet motor/generator, paired with a Powertrain Control Unit (HPCU) and DC/AC Power Electronic Converter (PEC) to convert the onboard 600V DC power supply into the 600V AC current required by the motor (and vice versa during regenerative braking). A DC/DC voltage converter supplies 24V DC to the chassis power supply, which powers the chassis electronics, bus interior equipment and recharges the 2x 12V lead-acid batteries. More details are explained under the Electrical Systems section (Page 2).

During normal operation, the I-SAM harvests energy during cruising or regenerative braking. Power is supplied through a Junction Box for energy distribution and as the electrical centre of the bus, with accompanying fuse box.

Both the energy storage system and the I-SAM electric motor are water-cooled.

In summary, the Volvo B5LH hybrid driveline contains the following major components:

- Euro 6 diesel engine (Volvo D5K240)

- Electric motor/generator (I-SAM)

- Energy Storage System (600V Li-Ion battery)

- Volvo I-Shift automated gearbox

Next Page (Page 3):

- Electrical Systems

- Pneumatic Systems & Peripherals

- Roof-Mounted Components

- Photo Gallery