The design of public buses in Singapore has steadily evolved to make public transport more accessible and convenient. Since the late 2000s, older high-floor bus models with stepped entrances have been phased out in favour of low-entry and low-floor models — both designed to make boarding easier for passengers of all ages and abilities.

Today, all public buses in Singapore are either low-entry or low-floor, with BYD C6 minibuses being the only exception. The local bus industry has trended towards a preference for low-floor buses, with the latest Land Transport Authority (LTA) specifications for new bus procurements usually calling for a low-floor layout.

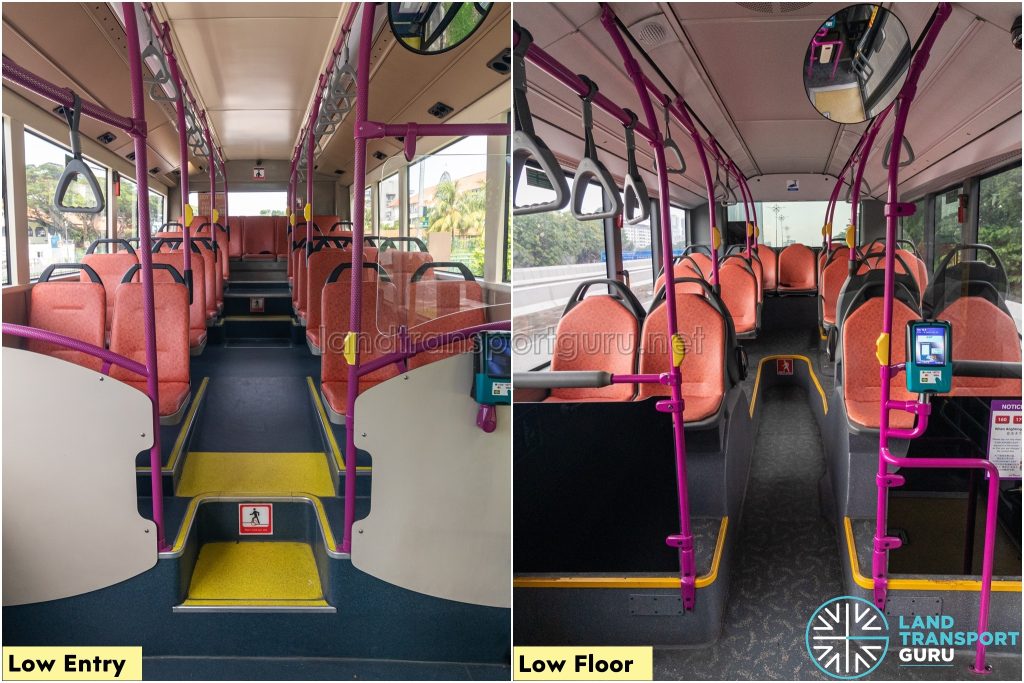

Low-entry vs Low-floor

While the terms “low-entry” and “low-floor” are often used interchangeably, they refer to two distinct interior layouts.

A low-floor bus features a continuously low and mostly level floor that runs from the front entrance to the rear seats. There are no internal steps, allowing passengers to move freely from the front to the back of the bus.

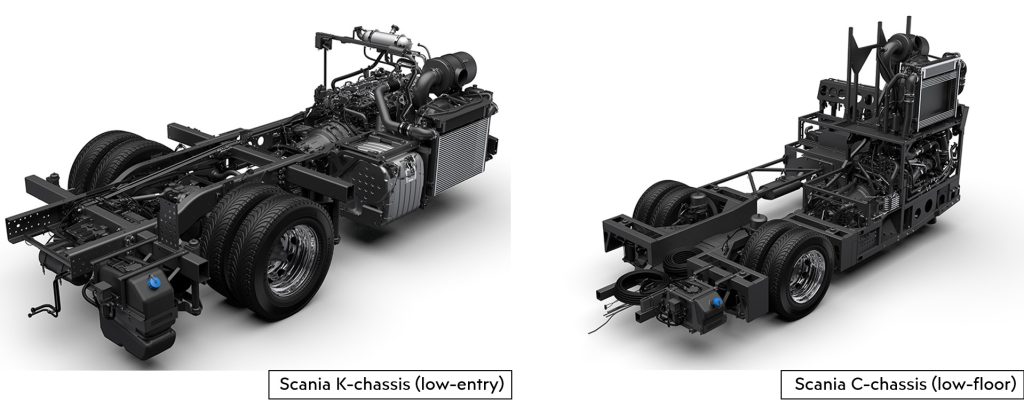

A low-entry bus, in contrast, combines a low front section with a raised rear floor. The area from the front door to the middle door remains step-free and accessible, while the rear section is raised by one or two steps. This design accommodates a conventional drivetrain layout at the rear.

To further improve accessibility, both bus types can also adjust their suspensions to “kneel”, to align the doorway with the kerb height — creating a step-free boarding experience for wheelchair users, parents with strollers, and elderly passengers alike.

Adoption in Singapore

Singapore’s adoption of accessible bus design began in the late 1990s. The predecessor of SBS Transit, Singapore Bus Service (SBS), introduced the first low-entry buses in 1998 with the Volvo B10BLE, followed by the Scania L94UB in 1999. These buses improved accessibility with their step-free entrances and priority seats at floor level.

SBS also adopted low-floor designs early, particularly for double-deck buses. The Volvo B10TL was introduced in 1999, followed by the Dennis Trident in 2001. Both models feature a full-low-floor layout.

In the mid-2000s, the switch to low-entry/low-floor buses would be driven primarily by accessibility, with an LTA mandate that all new public buses introduced from June 2006 must be wheelchair-accessible. This policy triggered large-scale procurement of low-entry single-deck buses — 1,101 Scania K230UBs for SBS Transit and 134 Mercedes-Benz OC500LEs for SMRT Buses. These low-entry models provided level boarding through the front and rear doors, with designated wheelchair bays in the front section.

In 2010, SMRT Buses introduced Singapore’s first low-floor single-deck bus, a Mercedes-Benz Citaro demonstrator (SMB136C). Commuters responded positively to its fully step-free layout, and both SMRT and SBS Transit ordered production batches of the Citaro in subsequent years, collectively adding over 1,000 units to Singapore’s fleet. From then on, all single-deck bus purchases were low-floor models.

For double-deck buses, the transition to a low-floor fleet took longer. Despite having introduced low-floor Volvo and Dennis models years before, the Volvo B9TL (CDGE) units introduced in 2006 and the early Volvo B9TL (Wright) buses delivered between 2010 and 2011 were both low-entry designs, with steps leading to a raised rear section. It was not until 2011 that low-floor Volvo B9TL buses began entering service, marking the final step in Singapore’s transition to a fully low-floor double-deck fleet.

However, this progress would not preclude the introduction of future low-entry buses, which make a slow comeback over the next few years.

Low-entry buses make a comeback

In 2017, LTA briefly trialled a MAN Lion’s City SD – 3-door Concept Bus. This prototype bus, whilst built on a low-floor bus chassis, was configured as a low-entry bus with three doors.

In 2021, 50 MAN A95 (Euro 6) 3-Door buses entered service. By modifying an existing low-floor MAN A95 chassis to incorporate a third door without redesigning the drivetrain layout, the aisle near the third door area requires ascending and descending steps, making it not truly low-floor—design differences between these buses and the full-low-floor ADL Enviro500 (3-Door) buses here.

In October 2025, LTA confirmed that it would modify its brand-new 3-door BYD BC12A04 and Zhongtong LCK6126EVG electric buses, following passenger complaints over tall step heights. A raised platform would be constructed between the 2nd and 3rd doors, to reduce the step height between the floor and the seat platforms, thereby converting these buses to a low-entry layout.

Modification work is expected to begin in October 2025. Modifications to these 420 buses are covered in a separate article here.

Bus Design Differences

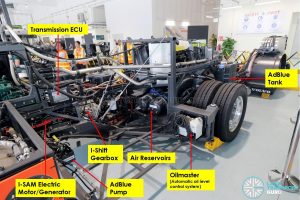

In low-entry buses, a standard drivetrain layout is used, with the engine and gearbox mounted horizontally at the back. The raised rear floor area allows sufficient underfloor space for engine and electrical components, which keeps maintenance straightforward. The two Scania chassis below provide a representative comparison between both layouts.

In low-floor buses, the need for a continuously flat aisle forces all components — the engine, electronics, and other systems — to be tucked away on the left or right sides of the chassis. Dropped axles are used for both the front and rear wheels so that the aisle can pass between them at a lower height; low-entry buses only use them for the front axle.

Mechanical components are also relocated under or behind the seats. This results in seats perched slightly higher than the aisle, often accessible by one or two small interior steps.

The trade-off is that while passengers enjoy a step-free path through the aisle on low-floor buses, the interior space also feels smaller. The wheel wells protrude further into the cabin, and this leads to more frequent use of rear-facing seats to make better use of the limited space. These seats can feel less comfortable for longer rides, and the narrow central aisle may also discourage passengers from moving to the back of the bus.

In contrast, low-entry buses such as the Scania K230UB or Mercedes-Benz OC500LE feature wider rear aisles and full-forward-facing seating layouts.

Chassis & Drivetrain Layout

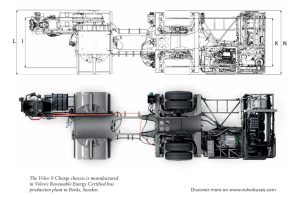

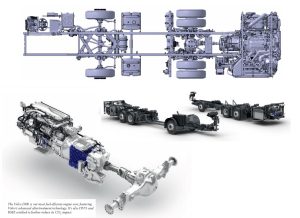

For low-floor buses, their driveline components (i.e. engine and gearbox) are offset to one side to accommodate the low-floor aisle. The left-offset driveline is most common in Singapore, as this is the default configuration for European bus manufacturers that design primarily for a left-hand-drive market, enabling a third door to be fitted on the right side.

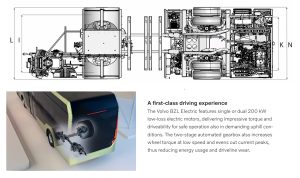

The same layout can be found on electric bus models that use a conventional driveline layout, with a drive motor connected to the drive axle via a driveshaft, e.g. Volvo, Yutong, Zhongtong models. Other manufacturers, like BYD and Mercedes-Benz, opt for an electrified drive axle (also called an electric portal axle), with wheel hub motors that are directly integrated into the drive axle.

On some low-floor bus models, functional components that cannot fit under the floorboard are housed in compartments that take up space within the passenger cabin.

For example, the Mercedes-Benz Citaro, MAN NL323F (A22) and MAN NG363F (A24) have radiators on the offside rear of the bus, which protrude into the passenger cabin, necessitating the removal of two seats in this area. Similarly, the Volvo B5LH positions the engine air intake, air filters, and charge air cooler in this area.

Passenger Experience

A low-floor bus offers a completely step-free interior from the front door all the way to the back. This means passengers can move easily along the aisle and enter/exit the bus without climbing steps, which benefits passengers with reduced mobility, parents with strollers, or anyone carrying heavy items.

This layout can also be more easily paired with a third door at the rear of the bus to accelerate passenger alighting.

For commuters, low-floor buses likely offer the smoothest experience, especially for routes with frequent passenger boarding and alighting, and short journeys where maximising seating capacity is less of a priority.

A low-entry bus, on the other hand, features a low floor only in the front and middle sections. This design retains the most important accessibility benefits of having a low-floor layout, notably for the elderly and wheelchair-bound, while keeping the rear area free to maximise seating capacity for longer bus journeys. Raising the floor above the wheels also allows for all front-facing seats, eliminating rear-facing seats that are less desirable.

Private Bus Operators

Low-entry and low-floor buses, while more restrictive than high-floor coaches in their seating capacity, have also seen use by private bus operators primarily for shuttle bus routes.

For instance, ComfortDelGro Bus bought both BYD B12A03 and Zhongtong LCK6126EVG (N12) low-floor electric buses for use as campus shuttle buses around the National University of Singapore (NUS) and Nanyang Technological University (NTU) since 2022. These buses also replaced older Volvo B9L low-floor diesel buses operating in NUS since 2015.

Tong Tar Transport also acquired Zhongtong LCK6125HQGA low-entry buses in 2016 for its RWS8 shuttle route. Between 2023 and 2024, it would also introduce Zhongtong LCK6126EVG low-floor electric buses, which primarily operate on the Mandai Shuttle.

Woodlands Transport also owns a fleet of low-floor Yutong ZK6126HGA diesel buses dedicated to Changi Airport shuttle routes. These buses come in three variants.

Gallery

High Floor Buses:

Low Floor Bus Chassis:

Bus articles with chassis coverage:

- BYD B12DS 3-Door double-deck bus for Singapore | Land Transport Guru

- Volvo BZL–SC Neustar City | Land Transport Guru

- Volvo B5LH – Chassis and Technical Overview | Land Transport Guru

- The making of a bus – MAN Lion’s City DD | Land Transport Guru

- Alexander Dennis Enviro500 – Euro 6 Chassis | Land Transport Guru

In the Philippines are all Low-Entry

A pity the Volgren bendies weren’t the low-entry GN version.

Probably unlikely that it would have even happened given that TIBS made a massive bulk purchase of high-floor O405Gs, in order to save on cost and to utilise economies of scale

Even a handful of demos could suffice.