In the many months since April 2017, signalling system faults have been the consternation of many commuters. The rollout of the new Communications-based Train Control signalling system, CBTC for short, has been particularly rough, with regular delays and faults across the North South Line (NSL) and East West Line (EWL), and the most severe incident being a train collision on 15 November 2017 that injured 38 people.

This article will attempt to delve deeper into the technical workings of the CBTC system and how certain working aspects of the system have led to the regular service delays faced by commuters. We will also discuss the policy side of the issue, including the challenges faced during the implementation of the CBTC and leading up to the full commissioning of the CBTC system.

The re-signalling is part of an overhaul of the entire North South and East West Line network. Other aspects of the overhaul are:

- Track Sleeper Replacement

- Power Rail Replacement

- Upgrading & Renewing of Power Supply System

- Track Circuit Replacement

- First-Generation Train Replacement

Key Milestones:

- 2012: Signalling upgrade starts, projected commissioning in 2016

- 2016 (Aug): Trial runs commence on the NSL during off-service hours

- 2016: Opening of Tuas West Extension delayed for more rigorous testing of the CBTC

- 2017 (28 Mar): CBTC live tested on the NSL for the first time, during the last hour of revenue service

- 2017 (16 Apr): Full-day CBTC testing on the NSL commences on Sundays

- 2017 (29 May): Daily full-day testing of the CBTC on the NSL (akin to full implementation)

- 2017 (18 Jun): Opening of the EWL’s Tuas West Extension and partial CBTC implementation

- 2017 (Jul): Trial runs commence on the EWL during off-service hours

- 2017 (15 Nov): Two trains collide at Joo Koon Station, injuring 38 people

- 2017 (Dec): Start of reduced train operating hours to accelerate resignalling work

- 2018 (03 Mar): CBTC concurrently tested on NSL and EWL for the first time, simulating regular operations

- 2018 (29 Apr): Full-day CBTC testing on the EWL commences on Sundays

- 2018 (26 May): Last day of legacy signalling system; entire NSEWL transitions to CBTC the day after

- 2018 (28 May): Daily full-day testing of the CBTC on the EWL (akin to full implementation)

- 2019: Formal commissioning on the NSL and EWL, old signalling system decommissioned

Background

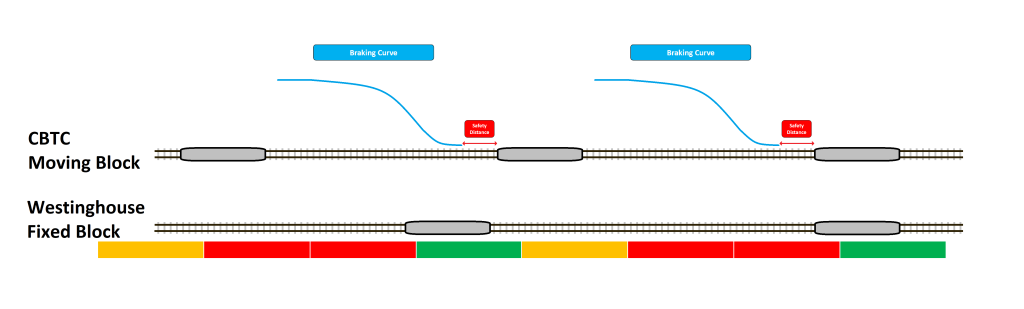

The North South Line (NSL) and East West Line (EWL) are the two oldest metro lines on the Singapore Mass Rapid Transit (MRT) network, which opened in stages between 1987 and 1990. The legacy signalling system fitted to the NSL and EWL since its introduction in 1987 was the Westinghouse FS2000 supplied by British company Westinghouse Signals Ltd (now part of Siemens). It relied on a fixed-block system that divided the track into ‘blocks’ which could only be occupied by one train at a time. Automatic Train Control (ATC) was supported through its ATP, ATO, and ATS subsystems, along with relay interlockings.

As part of the resignalling upgrade, French company Thales installed its SelTrac Convergence CBTC system to upgrade the legacy Westinghouse signalling system, along with its NetTrac MT management system. The signalling upgrade was part of a multifaceted expansion and upgrading of ageing infrastructure on the rail network, which included sleeper replacement, third rail and power system upgrading, installation of noise barriers, and the purchasing, refurbishment and replacement of rolling stock.

Thales touted its radio-based CBTC system as being highly reliable and advanced. It had previously provided CBTC for other rapid transit systems around the world, including the Kuala Lumpur Rapid Rail, Hong Kong MTR, London Underground, New York City Subway, Shanghai Metro and the Vancouver SkyTrain.

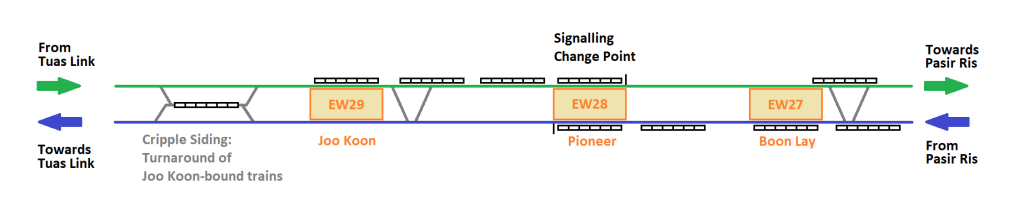

After the NSL fully transitioned to CBTC in May 2017, partial CBTC operation on the EWL followed in June 2017, where CBTC was activated between Pioneer and Tuas Link. All trains heading westbound switched from the legacy Westinghouse to the new Thales CBTC signalling system at Pioneer station, and switched back to the legacy Westinghouse signalling system when heading eastbound from Pioneer towards Pasir Ris. However, as a result of a train collision accident that occurred on 15 November 2017, the CBTC-equipped Tuas West Extension was isolated from the rest of the line from 19 November 2017 onwards until the completion of resignalling work in May 2018. Free Shuttle buses between Joo Koon and Gul Circle were provided throughout the duration of the closure.

The rollout of the CBTC was closely coordinated between the Land Transport Authority (LTA), the statutory board that owns all rail assets; SMRT Trains, the operator of the NSL and EWl, and Thales, the signalling system supplier.

But first, what is CBTC?

Main Article: Communications-based Train Control

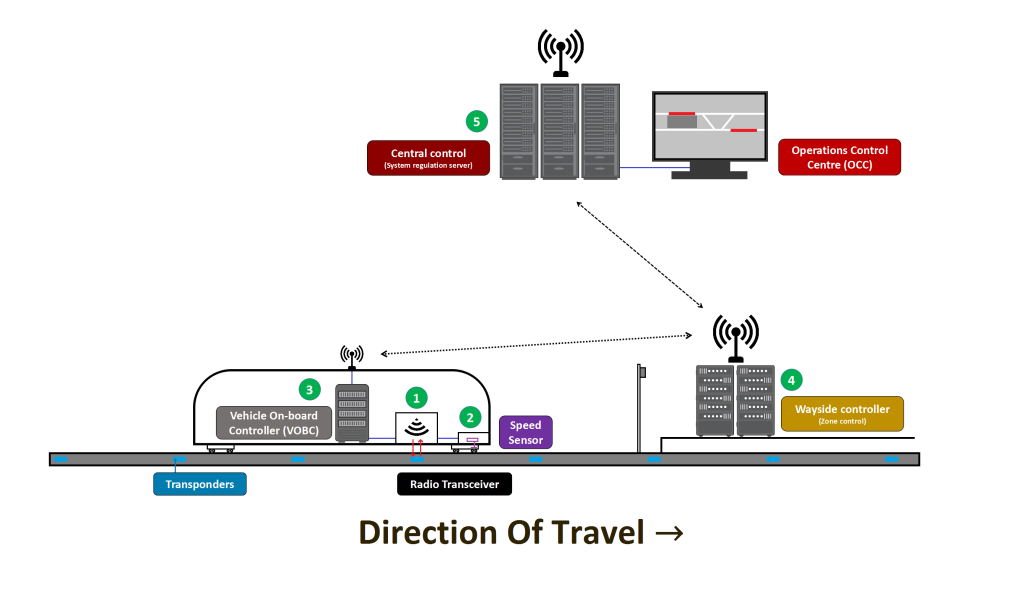

Communications-based train control (CBTC) is a moving block type railway signalling system that relies on continuous telecommunications between the train and trackside equipment for train management and control. The CBTC system on a train communicates real-time location and speed data with the trackside computers, which establish a safety envelope in which a train is allowed to operate. Before it gets too technical, in layman terms, the CBTC allows trains to operate closer to each other while maintaining a safe distance.

In Singapore, the CBTC signalling system is used on the North East Line, Circle Line and Downtown Line. The North South Line and East West Line, being the oldest lines in the network, were most recently upgraded from a speed-signalled Fixed Block signalling system to a new CBTC signalling system, commissioned in Year 2017 and 2018 for both lines respectively.

The CBTC system on a train communicates real-time location and speed data with the trackside computers, which establish a safety envelope in which a train is allowed to operate. This is in contrast to the legacy Westinghouse signalling system which uses divides the track into segments called ‘blocks’, which only can be occupied by one train at one time.

Readers keen on learning more about the general working principles of the CBTC contrasted with that of the legacy Westinghouse signalling system are highly encouraged to visit the main CBTC article, Communications-based Train Control.

While ‘CBTC’ is frequently used as an all-encompassing term for the new signalling system, Communications-based Train Control is, strictly speaking, is just the train separation component of the upgraded signalling system. The system contains, Automatic Train Operation (ATO), Automatic Train Protection (ATP) and Automatic Train Supervision (ATS) subsystems, which work together to offer Automatic Train Control (ATC) capabilities.

How does CBTC compare with the old signalling system?

The CBTC system uses existing track space more efficiently, safely reducing the space between trains, making room for additional services. On the North South Line and East West Line, the CBTC upgrade brings down waiting times 120 seconds to 100 seconds, allowing for a 20% increase in capacity, and a maximum of 36 trains per hour over the current maximum of 30 trains per hour.

This will be accompanied by the delivery of 57 new trains (45 C151B and 12 C151C trains) for both lines by 2019, greatly reducing peak hour congestion on these lines in the years to come. It is also supported by modernised ATP, ATO and ATS subsystems.

The system can also adjust train speeds, reduce train bunching and recover from delays. Trains are also able to operate on all tracks in both directions safely. This offers more flexibility for trains to switch between tracks when there is a fault on one stretch of track.

On the North South Line and East West Line, trains previously operated with fixed-block signalling. Under Semi-automatic Train Operation (STO), the Train Operator closed the doors at every station and operated the train manually during wet weather or during a disruption. After the CBTC upgrade, both lines switched to Driverless Train Operation (DTO), where doors close automatically. The system will not require input from the driver, unless in the event of a disruption.

The CBTC is advantageous even in wet weather, where trains will automatically adopt a suitable wet weather braking profile when the rails are wet, without the need for manual driving. In the old signalling system, the braking forces demanded by the Automatic Train Control (ATC) are optimised for dry weather and would cause the wheels to slip during wet weather, resulting in platform overruns. As such, Train Operators manually controlled the train in Coded Manual, CM (also known as Protected Manual Mode, PMM), resulting in a more jerky ride and prone to underruns and overruns. Under CBTC, trains in wet weather will adopt a more gentle braking profile to avoid wheel slippages, and the additional time taken between stations are automatically factored into the scheduling system.

Hardware and Software upgrades

The new signalling system involved the installation of additional signalling equipment on board every existing train on the NSL and EWL. As such, two seats were removed from both ends of every train and a signalling equipment housing unit was installed in its place. The unit houses the Vehicle On-board Computer (VOBC), and includes ATC equipment as well as relays. Two units are installed on every train, offering redundancy as each computer can assume the working role of the other in the event of a system fault. In addition, the Train Operator’s console had to be modified to accommodate the human-machine interface (HMI), the CBTC display unit.

New infrastructure was also installed. New trackside equipment such as antennas and associated cabling were installed along the tracks, and wayside controllers (new computer systems) had to be fitted to existing train stations. The Operations Control Centre also had to be reconfigured for CBTC operation.

While the CBTC no longer requires existing track circuits for operational use, they are still retained to be used as a backup system for train detection and for broken rail detection. Although not equipped with the fixed-block signalling system, the Tuas West Extension is also fitted with track circuits for this reason.

Implementation Timeline & Challenges

Resignalling projects present a unique difficulty since signalling systems are critical to the operation of trains and rely on the near-flawless operation of its many constituent components to operate smoothly. Minor software glitches or hardware issues can cascade into long delays. As such, rigorous testing is crucial to the successful rollout of a new signalling system.

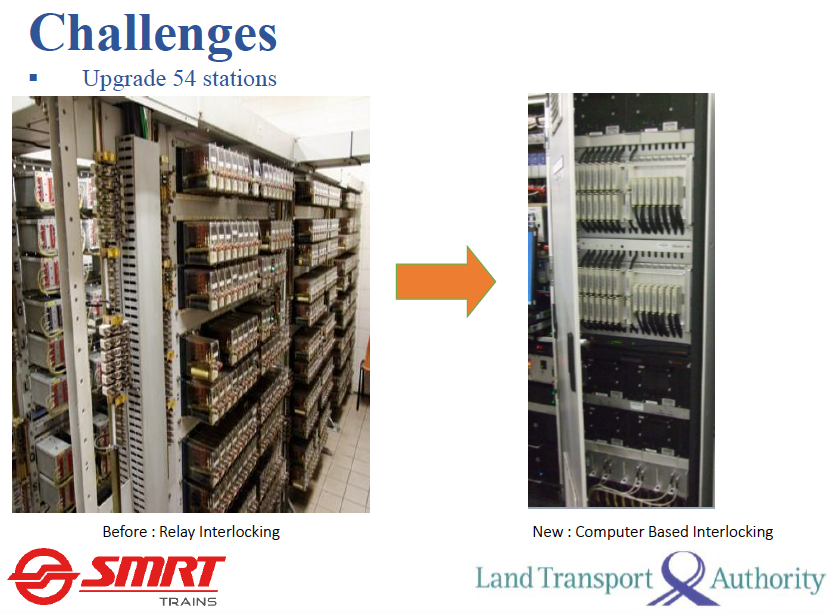

In February 2012, Thales was awarded Contract 1652A – Replacement Signalling System for the North-South And East-West Lines and Contract 1652B – Signalling System for Tuas West Extension for S$195 million and S$40.3 million respectively. Resignalling work was coordinated among SMRT, LTA and Thales engineers. The upgrading work would be carried out across 95km of tracks, 141 trains, 54 stations, 1 main operation control centre, and 3 depots (Bishan Depot, Ulu Pandan Depot, and Tuas Depot) from which trains are deployed. It was later understood that Changi Depot was also equipped with the CBTC signalling system.

As a brownfield application of the CBTC, re-signalling an operational line presents significantly greater challenges than a greenfield application (i.e. on new rail lines). Previous applications of the CBTC in Singapore (on the NEL, CCL and DTL) involved intensive daily testing for several months prior to the opening of the line. The NSL and EWL resignalling did not have the luxury of shutting down the line for long periods of time, and testing had to be confined to off-service hours (also known as engineering hours) for much of the resignalling period.

For the NSEWL, the signalling upgrade started in 2012 and was intended for commissioning by 2016. That deadline was missed and pushed back to 2017. In the meantime, the opening of the Tuas West Extension was pushed back to 2017 for more rigorous testing of the new signalling system. While the reasons for the delay were never formally announced, there was a possibility that other upgrading work, such as sleeper replacement, took priority over the resignalling.

Much of the testing work was carried during engineering hours. In addition, the delays affected the launch of SMRT’s newest trains, the Kawasaki Heavy Industries & CSR Qingdao Sifang C151B (or simply C151B), of which all 45 trains had been delivered. The new C151B train is easily identified by its white exterior and is only equipped with the CBTC signalling system and as such, requires the CBTC signalling system to be active in order for it to be deployed on the line.

The opening of the Tuas West Extension was indirectly affected by the launch of the C151B trains. As CBTC was not commissioned on the EWL, only older trains (equipped with both the legacy fixed-block and new CBTC signalling systems) could ply the full stretch of the line. These older trains could be freed up by redeploying them from the NSL, but only after C151B trains were introduced to cover the shortfall on the NSL. Hence, when the Tuas West Extension opened three weeks after full-day CBTC testing began on the NSL, at least 10 C151B trains were already in service on the NSL. On a smaller scale, the additional trains also helped to accelerate the body shell replacement of the older C151A trains which were being sent back to China for repairs.

Implementation Process

Much of the testing work was carried out during engineering hours, limited to between 1.30am and 4.30am. This three-hour window was crucial, as beyond that, time was need to prepare stations and trains for the start of revenue service at 5:30am. Apart from over 1,300 tests required to ensure the core functionality of the signalling system, the CBTC was also run in ‘shadow mode’ during regular operating hours, where it was turned on for monitoring and data recording purposes. This mimicked an actual operating scenario whilst the trains remained driven by the old signalling.

Brief Timeline – North South Line:

CBTC Live Testing began in the late hours of 28 March 2017, during the last hour of revenue service, when all trains were stopped at around 11pm (for around 10 minutes) to facilitate the switch to the new system, up till the end of revenue service hours past midnight. These tests were carried out across the next few days, for a total of 10 rounds of testing. Full-day testing of the system commenced on 16 April 2017 (Sunday) and continued every Sunday for the next two months for a total of 7 rounds of testing.

With no major issues found during these live tests, the decision was made to proceed with full-day weekday testing (akin to full implementation) of the CBTC system, which commenced on 29 May 2017, deliberately timed with the start of the month-long June school holidays to lessen the inconvenience on students.

Brief Timeline – East West Line:

After the open house two days prior, partial implementation of the CBTC commenced on 18 June 2017 with the opening of the Tuas West Extension. Trains switched from the old Westinghouse fixed-block system to the Thales CBTC system at Pioneer Station (in both directions). However, in the wake of a train collision incident at Joo Koon Station on 15 November 2017, CBTC and legacy signalling systems were physically separated until CBTC resignalling works on the entire line were complete. Free Shuttle buses between Joo Koon and Gul Circle were provided throughout the duration of the closure.

The incident marked a crucial turning point in the CBTC rollout, where shortened operating hours (comprising early closures, late openings and Sunday full-day closures) were implemented across sections of the EWL between December 2017 to April 2018 to accelerate resignalling works. Unlike the NSL resignalling, CBTC testing during the last hour of revenue service was not carried out.

Full-day testing of the system commenced on 29 April 2018 (Sunday) and continued every Sunday until end-May 2018 for a total of 5 weekends of testing. Full-day weekday testing (akin to full implementation) of the CBTC system started on 28 May 2018, deliberately timed with the start of the month-long June school holidays to lessen the inconvenience on students.

Other Challenges

Unlike the North East Line, Circle Line, or Downtown Line, which operates on a single type of train (Alstom Metropolis for the NEL and CCL, Bombardier MOVIA for the DTL), the North South Line and East West Line operate on four distinctly different type of rolling stock, namely the Kawasaki Heavy Industries C151, Siemens C651, Kawasaki-Nippon Sharyo C751B and the Kawasaki-Sifang C151A / C151B. A total of 141 trains were upgraded with the Thales CBTC signalling system.

Each of the four fleets of trains is different on a technical level, with different types of traction motors and existing on-board equipment, so the signalling had to be adapted for each type of train. Moreover, in contrast to the fully-underground new lines, the NSL and EWL run on viaducts, at-grade sections and underground tracks, and brings about the challenge of adapting the system for all these different types of trains in different track conditions (i.e. dry and wet weather). During wet weather, trains adopt a modified braking profile with a greater braking distance to compensate for the reduced track adhesion during wet weather.

In addition, the signalling system had to be adapted to interface with existing technologies such as the Rail Travel Information System (RATIS) screens at stations and multiple types of Platform Screen Doors (PSD) installed across the line. With the introduction of the CBTC signalling system came the challenge of integrating these existing technologies to work with the new signalling system.

Faults and Failures

The CBTC implementation resulted in many faults and delays with both the NSL and EWL during the early months of operation.

On the NSL, regular signalling faults and delays caused long headways and instances of very close ‘bunching’ along the line. While the CBTC system proved effective in running trains together at very tight intervals, the cause of such ‘bunching’ incidents was often the CBTC system itself, when minor signalling issues often delayed individual trains and causing long headways followed by a quick succession of ‘bunched’ trains (trains arriving in quick succession).

Despite the relatively fault-free performance of CBTC on the EWL (after all, the Tuas West Extension was the most rigorously tested stretch of line prior to implementation), the signalling change point turned out to be a significant weak link. The changing of signalling systems at Pioneer was supposed to take 2 minutes, but frequent delays (especially during the peak hours) led to significant backlogs east and west of Pioneer Station. Westbound congestion often stretched to Lakeside and beyond, even reaching to Jurong East in extreme circumstances.

Fortunately, lessons learnt during the early implementation stages was incorporated into the CBTC signalling along the entire EWL, resulting in a much smoother implementation.

Scenarios Faced

Most of the scenarios described here were encountered during the early phases of CBTC implementation and resolved several months into testing.

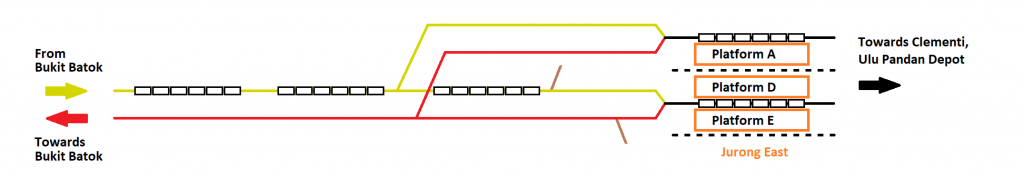

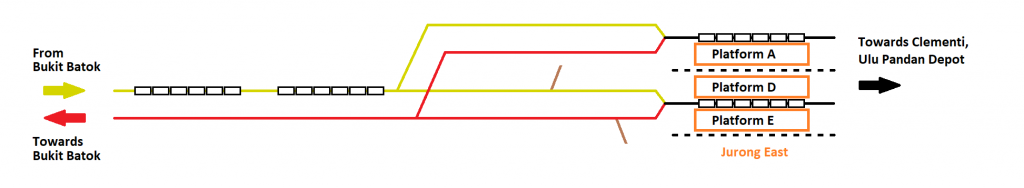

Scenarios Faced – NSL Jurong East bottleneck

With trains operating at higher frequencies under the CBTC, train bottlenecks regularly occurred at Jurong East, one of the terminating stations of the NSL. As a result, commuters frequently faced additional travelling time between Bukit Batok and Jurong East during the peak hours, as trains queued up to enter Jurong East.

The turnaround duration at Jurong East is determined by the CBTC signalling system, as is the automated door closing at every other station. As such, there is a risk that commuters might get struck by closing doors especially while transferring from EWL to the NSL. Previously, Train Operators would manually close the doors at an appropriate moment by monitoring the platform situation through CCTV monitors, while also holding the doors for commuters transferring from the EWL.

Fresh trains from Ulu Pandan Depot were also required to switch signalling systems. On the NSL, trains are launched from both Bishan Depot and Ulu Pandan Depot. Bishan Depot is located along the NSL, which means trains dispatched from Bishan Depot were already operating on the new signalling system. However, Ulu Pandan Depot is on the EWL, which means that when trains are dispatched from Ulu Pandan to Jurong East station, trains had to switch from the old signalling system to the new one.

As explained during a media briefing on 14 July 2017, the signalling switch at Jurong East station took about one-and-a-half minutes, and during the morning peak hour where trains operate at a headway of about two minutes, the switching caused delays and congestion which impacted commuters’ journeys.

Scenarios Faced – EWL Pioneer bottleneck

All westbound East West Line trains, terminating at either Joo Koon or Tuas Link, had to switch to the new signalling system at Pioneer MRT Station (Platform B). This is because Joo Koon-bound trains turn around at a cripple siding west of Joo Koon Station, built as part of the Tuas West Extension which is equipped only with the CBTC signalling system.

The signalling switch-over process was said to take about 2 minutes. However, the actual time required to switch between signalling system varied from as fast as 30 seconds to as long as 5 minutes, and even longer should a train or signalling fault occur. With the peak hour train frequency of about 2.5 minutes, delays in the switching of signalling system at Pioneer in either the Eastbound or Westbound direction regularly caused bottlenecks as trains queue up to enter the station.

As a result, commuters would have likely encountered slow-moving trains and “stop-go stop-go” scenarios from Lakeside to Pioneer as trains bunched close together. In the Eastbound direction, commuters would have faced long wait times for trains if there was a delay in switching signalling systems, giving rise to long headways and overcrowded trains.

Jurong East crossover wait point

One scenario observed at Jurong East was the location at which trains stop to wait for the front train to exit the station. When CBTC was first implemented on the NSL, trains heading into Jurong East stopped before the first crossover point which directs Platform A and Platform D, which is around half the distance between Jurong East and Bukit Batok. Trains would then proceed to wait there until the front train occupying either Platform A or D left the station. This scenario left a lot of unoccupied track before Jurong East, increasing the amount of time when between train departures/arrivals at Jurong East Platforms A/D and thereby decreasing the rate of train turnarounds.

After several days, the system was modified to allow trains heading into Platform D to stop just before the crossover point that leads to the eastbound East West Line (Jurong East Platform B/C), as illustrated in the scenario diagram above (NSL Jurong East bottleneck).

While the reason for this scenario is unclear, a brochure for the Thales NetTrac MT central control system reveals a feature known as Automatic Deadlock Prevention, which prevents deadlocks in a bi-directional single-track travel area. It works by preventing the issuing of route request until a train at the terminal is at a location where it will clear the interlocking just before the second train required the route to be set. There is a possibility that this system prevents a train from entering what is perceived to be a bi-directional track and thereby preventing an incoming train from entering the sector before an exit route has been finalised for the front train occupying the platform at Jurong East.

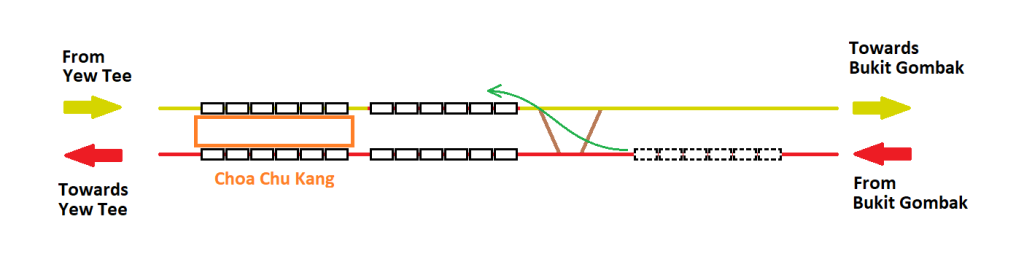

Trains entering wrong sections of track

Another scenario observed was where trains abruptly entered sections of track when they are not supposed to, resulting in obstruction of other trains on the line and subsequently delays. For example, a train waiting to enter Jurong East would overshoot its waiting position, pass over the final crossover point and come to a stop just before the platform, blocking the train at the platform from exiting the station. Delays resulted as the offending train had to reverse, to allow room for the train at the platform to leave the station.

Another scenario observed was during bunching at Choa Chu Kang towards Jurong East, where a southbound train abruptly crossed over to the northbound track after leaving the station. While safety mechanisms prevented a collision with a northbound train on the same track, the offending train had to be reversed back onto the southbound track.

Other faults

Platform overrun and reversing

Under CBTC operation, trains occasionally overran the station platform, regardless of wet or dry weather. As a result, trains have to reverse back into the station, resulting in minor delays. Many possible factors include incorrect detection of the alignment device, or a braking curve not ideal for the weather scenario. Progressive software updates have reduced the speed of trains on rainy days.

Train doors do not open, skips station

Trains occasionally stopped at the correct position but then proceed to the next station after a short dwell period without ever opening the doors. Complaints about this scenario often appeared on SMRT’s social media platforms. This scenario was likely caused by the Vehicle On-board Computer (VOBC) unable to detect the presence of the alignment device at the end of each platform.

Doors close too fast & Announcement glitches

Under the old signalling system, the timing of the “Doors are closing” chime is controlled by the Automatic Train Supervision (ATS) – the ATC subsystem that governs schedule adherence – and automatically plays before the scheduled departure of the train from the station. It is then the job of the Train Operator to close the doors at an appropriate moment to avoid closing the doors on passengers, before setting the train in motion.

However, under the new CBTC signalling system, the “Doors are closing” chime, doors closing action and actual departure timing of the train are all governed by the signalling system. Occasionally, the system may leave too little time for boarding and alighting activities especially at interchange stations, which is a source of complaints.

Apart from the doors closing sequence, the announcement system was sometimes observed to play incorrectly, occasionally abruptly cutting them off normal announcements, repeating them, or playing them out of sequence. This scenario was also encountered during the early periods of EWL CBTC operation.

Interfacing between Platform Screen Doors & Train Door

With CBTC, train doors and platform screen doors opened and closeed in sync, instead of the short lag time between the opening and closing of both the platform screen doors and train doors under the legacy Westinghouse signalling system. Issues affecting the interfacing between the train doors and platform screen doors resulted in either set of doors failing to open or close, resulting in delays as the train is unable to move off until the CBTC signalling system confirms that both doors are closed.

A prominent example of this scenario happened during the revenue service launch of the C151B train (Set 601/602), when the NSL was undergoing Sunday full-day trials. At City Hall station (towards Jurong East), the train was delayed for around eight minutes as the system failed to detect that both sets of doors were closed, resulting in a backlog of trains.

Abrupt braking during normal operations

Under CBTC operation, trains engage the emergency brakes as a safety measure when there is a loss in radio communication between the train and wayside controllers, or any form of incorrect or conflicting signals are received. This occasional glitch is the reason for the out-of-the-blue abrupt braking scenarios that some commuters might have experienced.

A computer system error leading to incorrect/conflicting signals was the cause of the island-wide train disruption on 28 June 2017. The system error was caused by Thales engineers missing a step while loading a new radio software. The resulting error disrupted radio communications between trains and lineside antennas, and all trains along CBTC-equipped sections of the NSL and EWL came to a standstill.

Information Screen bugs

The Rail Travel Information System (RATIS) screen on platforms, which indicate the arrival time and destination of the approaching train, tends to glitch by displaying the subsequent station as the destination rather than the actual terminating stop of the train. For example, a train at City Hall heading towards Marina South Pier might display “Raffles Place” for any amount of time, as shown in the picture on the right. Passengers are encouraged to just board the train regardless of the destination shown as the destination may be incorrect.

During the early days of CBTC testing, the RATIS would also not indicate the platform at which the train will arrive Jurong East at (either Platform A or Platform D). This issue has since been resolved.

Other scenarios

Changi Depot not CBTC equipped? (Verified False)

While Bishan Depot, Ulu Pandan Depot, and Tuas Depot were installed with CBTC, Changi Depot is the only depot to be not fully upgraded to CBTC. This is because the depot will be replaced by the future East Coast Integrated Depot which is targeted for completion in Year 2024.

Correction note: this section has since been verified to be untrue; Changi Depot is understood to also have received the CBTC signalling system.

PMSM trains redeployed to Changi Airport Line

For several weeks after the opening of the Tuas West Extension (18 June 2017), C151 trains upgraded with IGBT-VVVF Permanent Magnet Synchronous Motors (PMSM) from Toshiba were fully redeployed to the Changi Airport Line between Tanah Merah and Changi Airport, away from entering the CBTC equipped sectors west of Pioneer. While the reason for this redeployment is unclear, there might have been the desire to avoid initial complications. PMSM-equipped C151 trains returned to the mainline EWL since early July 2017.

Friction Brake usage

Commuters may have noticed a pungent metallic smell similar to a burning rubber smell at stations when travelling on the NSL and EWL, and especially along CBTC-equipped sections of track. That is the smell of the friction brakes.

Under normal operating conditions, trains use the traction motors to slow down from higher speeds in a process known as regenerative braking, returning current to the third rail at the same time. However, under the CBTC, the friction brakes engage more frequently as the trains often engage in more abrupt braking, and when they start to overheat, the smell is produced. This scenario is most prevalent in the first-generation C151 trains, where friction brakes are often used excessively. It appears that fine regenerative braking control on C151 trains is less strong than that on other types of rolling stock.

Another scenario of heavy friction brake usage is during wet weather, where trains frequently engage friction brakes to stop the train in their precise stopping positions.

Official Explanation

Since the start of CBTC operations in 2017, the frequent use of friction brakes on C151 trains have led to commuter complaints about the burning smell. Since July 2018, this issue has yet to be resolved, with many C151 trains suffering from this issue (some trains were observed to decelerate from operating speed using solely the friction brakes). For commuters, the smell is most prevalent near the gangways and ends of the train where the bogies are located.

In July 2018, a Facebook user (Zhou Joycelyn) posted an enquiry to SMRT’s Facebook page, containing a screenshot of an email wherein SMRT addresses the source of the burning smell. In the email, SMRT mentioned the use of fibre asbestos in the brake pads, which raised concern among Facebook users since asbestos was a hazardous material, the use of which was prohibited by the National Environmental Agency (NEA) since the late 1980s. In its media response to the Straits Times, SMRT retracted its earlier explanation involving asbestos. It assured the public that asbestos was not used on its network, and added that it was “working with the Land Transport Authority on reducing such occurrences (burning smell) on the network”.

Issues related to excessive friction brake usage were largely resolved by the end of 2018.

Accident

Main Article: MRT Trains collide at Joo Koon (Sequence of events), Suspension & Changes to Train Service on Tuas West Extension (Resulting service suspension), CBTC Implementation Part 2 – Train Collision (Full accident write-up)

During the morning peak hour of 15 November 2017, at around 8:20 am, a moving train collided into the rear of a stationary train at the westbound platform of Joo Koon MRT Station with 38 injuries. Two C151A trains, trainsets 535/536 and 547/548 were involved, and the incident occurred within a CBTC-controlled section of the EWL. The incident was attributed to a software fault when transitioning between the old and new signalling systems.

Amidst the unprecedented circumstances leading to the collision (in-depth report in the dedicated articles), the progress of CBTC resignalling and public confidence in the new system was severely dented as a result. For many, this incident was the crux of the failures involving the CBTC resignalling project, where commuters endured months of less-than-reliable service standards as a direct result of resignalling work.

As a result, the CBTC and legacy signalling system-equipped sections of the EWL were fully isolated until the completion of resignalling work. This led to the deployment of full-day shuttle bus services between Joo Koon and Tuas Link between November 2017 and May 2018.

Shuttle Bus Main Article: Joo Koon—Gul Circle Free Shuttle Bus Service.

In the wake of the accident, signalling system provider Thales also opened a CBTC Signalling Simulation Facility in Bishan Depot, which augmented ongoing CBTC trials by simulating the reliability and robustness of the new signalling system under different test scenarios. These simulations were conducted without impacting actual train services, and were tailored to the environmental and infrastructural conditions of the rail network in Singapore.

Fine-tuning the system

Since the start of the CBTC revenue service trials, engineers from LTA, SMRT and Thales have been continuously fine-tuning the system to suit local conditions and ironing out existing glitches.

A software update was installed on the new signalling system on the North-South Line (NSL) after passenger service hours on Friday, 14 July, to further fine-tune the ongoing testing by the Land Transport Authority (LTA), SMRT, and system supplier Thales to stabilise the system after having undergone full-day testing since 29 May 2017. This was the only software update announced, although many more are certain to have taken place.

Incident Management

During a fault along CBTC-equipped sections of track, SMRT would activate its Rail Incident Management Plan (RIMP) to deal with the incidents. Delay announcements would be broadcasted across NSL and EWL stations, along with updates to social media platforms.

In the case of prolonged delays, free bus boarding at affected stations, as well as stations leading up to the affected stretch (which are indirectly affected due to train bunching, are activated. Depending on the severity of the incident, rail bridging bus services may also be offered. To improve its incident response times, SMRT also set up Task Force 50 as a standby pool of bus drivers and buses to be quickly activated for rail bridging bus services.

SMRT also offers printed guides on alternative travel arrangements, which are available at all stations and distributed in the event of a disruption. Commuters can get a refund for an incomplete journey at any TransitLink Ticket Office up to 7 days after a disruption.

Announced & Future Plans

Despite the issues early into CBTC implementation, SMRT expected that the CBTC signalling system on the NSL would stabilise by November 2017 – January 2018, and should be fully operational by May 2018, a year from when testing during passenger service started. A similar timeline was reported during resignalling works on the London Underground’s Jubilee Line, requiring about 6 months to bring the failure rate down to acceptable levels.

As confidence in the new signalling system grows, only then would SMRT add more trains to the line during the peak hours to maximise the benefits of the CBTC signalling system. After being fully commissioned, the legacy Westinghouse signalling system will be decommissioned, and associated hardware will be uninstalled.

For the East West Line, CBTC testing on certain stretches began in July 2017 across several stations. Live testing of the CBTC on the EWL was formerly projected for December 2017, again coinciding with the month-long school holidays for minimum disruption to students. However, this timeline was scrapped in the wake of the Joo Koon Train Collision and CBTC live trials was pushed back to May 2018.

Early Closure, Late Openings, Full-Day Closures

Accelerated upgrading of the new CBTC Signalling System had been carried out through additional engineering hours as part of Early Closures, Late Openings and Full Day Closures. From December 2017 till the first week of March 2018, LTA, SMRT and signalling supplier Thales had completed the equivalent of more than 40 nights of additional installation and testing work for the new signalling system on the East West Line (EWL). This has helped to accelerate the EWL re-signalling programme by six months, bringing forward the completion to June 2018. In fact, full-day live testing began in April 2018 (on Sundays) and May 2018 (daily).

See Shortened Operating Hours for Rail Renewal Work for a timeline and further details of each closure episode.

Our Take

A common topic in public discourse is how the CBTC signalling system could have been better implemented to reduce its impact on commuters. Unfortunately, there is no easy answer to this question. While many lessons have been learnt from implementing CBTC overseas, no two metro systems are identical, and each resignalling project is a challenging endeavour for engineers.

Difficulty of resignalling projects

Resignalling projects tend to be difficult to manage, as is the experience with other metro systems such as London, New York and Kuala Lumpur. As such, metro systems tend to proceed cautiously and roll out upgrades in phases before full commissioning.

However, this was not the case with the North South Line. Rather than proceeding in stages (e.g. expanding testing to weekends, off-peak hours, and finally peak hours), the decision was made to jump straight into full-day weekday testing despite just 7 days worth of weekend testing. And as faults unravelled one after another during weekday testing, so did the consternation of many passengers.

In particular, signalling systems rely on the reliable function of its many component parts to deliver a reliable, working system. As such, the minor technical glitches escalated into major delays that brought peak hours chaos during the early weeks of full-day weekday CBTC testing on the NSL. The question of reliability often surfaces, and despite what LTA/SMRT have said about the multiple redundancies of the signalling system, understandably left many questioning the reliability of the signalling system. In the bigger picture, the rushed rollout of the signalling system (likely to coincide with the June school holidays) could have left underlying issues not fully assessed before peak hour testing.

Despite public suggestions to confine signalling tests strictly to off-peak hours, peak hour testing is necessary to ‘stress test’ the system, as there is no effective way of simulating such conditions during off-peak hours. Apart from the short headways between trains, the signalling system has to cope with high passenger loading on trains, which affects the performance characteristics and braking profile under automatic operation. Factoring in the unique characteristics of four different types of trains on the NSL, coupled with the chance of wet weather along certain stretches of the line, putting the new CBTC signalling system through its paces must be conducted in a challenging environment such as that presented during peak-hour testing.

C151B Deployment

Furthermore, the deployment of the C151B trains on the NSL essentially gave LTA/SMRT no room to back out of CBTC testing. As explained in an earlier section (Implementation Timeline & Challenges), the new C151B trains were only equipped with the CBTC signalling system and had to be deployed on the NSL, otherwise, there would be insufficient trains for the Tuas West Extension.

This also meant that it was not practically feasible to revert back to the legacy Westinghouse signalling system in the event of a major disruption, as the C151B trains were incompatible with the legacy Westinghouse signalling system. They would have to be stabled at an available siding or a depot, away from the main line before a signalling switch can be put into effect. In essence, it would be very difficult to pull off a signalling switch during operational hours owing to the difficulty of taking the C151B trains out of service. By June 2017, there were more than 10 such trains deployed on the North South Line daily.

Partial Line Implementation

Partial line implementation could have been rolled out on the NSL to more rigorously test the CBTC, similar to what was done for the Tuas West Extension, with trains switching signalling systems at a certain station along the line. However, that would affect plans to deploy C151B trains on the North South Line, which can only operate on CBTC-active sections of track. This would make partial implementation difficult.

Another alternative would be to operate a shuttle train service with commuters having to change trains at a certain station (e.g. Ang Mo Kio) and not having to switch signalling systems. Such an approach was taken in Kuala Lumpur during the CBTC rollout of the LRT Ampang / Sri Petaling Line where one set of trains were equipped with the legacy system only and another set of trains with the newer CBTC system only. The line had to be operated as a shuttle service, with commuters having to change trains between CBTC and legacy system-equipped sections of track at a designated transfer station.

However, this approach would be inconvenient and cause unnecessary trouble, for C151B trains comprised a very small part of the NSL operating fleet, and SMRT/LTA might not have seen the need for more rigorous testing of different sections of track when no issues were detected early in the testing phase. Combined with the rushed implementation of a signalling system already behind schedule, such an approach was not taken. In hindsight, the initial complications with switching signalling systems as surfaced during the Tuas West Extension rollout (where trains switched signalling systems at Pioneer) might have defeated the purpose of partial implementation.

Weekend closures for smoother implementation?

A key advantage to Thales’ resignalling proposal was the promise of no passenger service closure. It was a promise that won the contract over several major international rail systems providers, such as Alstom, Bombardier, Invensys, Ansaldo STS and Siemens.

Such was the scenario when Thales was implementing the CBTC signalling system on the London Underground’s Jubilee Line. Upgrading and testing work necessitated the closure of sections of the Jubilee line each weekend during 2009. Although the project was due for completion in March 2010, the closures continued through 2010 and only finished in spring 2011. The programme of temporary closures for engineering work was criticised by many, and patrons to large event venues such as Wembley Stadium and The O2 had to rely on limited-capacity rail bridging buses.

As a major transport link serving the north of Singapore, any form of planned weekend closures would be very unpalatable to many commuters. Unlike the Jubilee Line within the dense London Underground network, the lack of duplicity of the North South Line would affect many commuters and require many bridging buses to cover affected sectors. As such, we predicted (in July 2017, at time of writing) that weekend closures would not be carried out for NSL and EWL CBTC implementation.

Early Closures, Late Openings and Sunday Closures

In hindsight, we were wrong about not expecting weekend closures. In the wake of the train collision incident, Early Closures, Late Openings and Full-Day Sunday Closures were implemented to accelerate resignalling work. These arrangements were necessary to accelerate the completion of EWL resignalling works from December 2018 to June 2018. These shortened operating hours consumed large amounts of resources, with hundreds of buses deployed on rail replacement services and manpower on the ground to assist commuters.

A list of shortened rail operating hours by month: (full list here)

- Early Closure, Late Opening of East West Line (Mar 2018)

- Early Closure, Late Opening of East West Line (Feb 2018)

- Early Closures, Late Openings, Full-Day Closures on East West Line (Jan 2018)

- Shorter Operating Hours on East West & North South Lines in Dec 2017

Full Day Closures on Sundays represented the largest challenge, with buses and manpower deployed in full force to keep commuters moving. A large number of buses inevitably led to congestion along roads and at bus stops served.

Conclusion

Taking these factors into consideration, along with the relative success of the CBTC during weekday testing, the decision was made to jump straight into full-day testing for the North South Line, and that was when the problems started. Despite many factors working against SMRT and LTA, compounded by LTA’s rushed schedule for CBTC implementation, made an unfavourable situation worse. It was only through multiple glitches and disruptions on the NSL that a more robust system was established.

Our take on SMRT’s Incident Management

During a delay, it was clear that SMRT’s rail incident management plan (RIMP) left much to be desired. Delay information was not being well disseminated to commuters in a timely manner. Delay estimates did not accurately reflecting actual travel time and did little to soothe the nerves of passengers at overcrowded stations who were late for appointments. Furthermore, in a delay, commuters were left in the lurch with regards to when services are expected to be restored, leaving them stranded at train stations without enough information to plan an alternative route.

Furthermore, SMRT does not announce instances of delays under 10 minutes on their social media platforms. This leaves commuters unable to substantiate their delays when rushing late for work or being late for appointments. Although commuters can request for delay chits at the Passenger Service Centres at affected stations, these offices would frequently be unstaffed or understaffed as staff members are busy attending to train service disruption/delay and guiding commuters. One can imagine the queue in the City if every office worker lines up to get a delay chit during the rush hour.

A better alternative is the prompt dissemination of delay information on dedicated social media channels. Like many overseas rail operators, it also issues delay certificates online in PDF form on their website, where affected commuters can download as proof of their delay. (SMRT rolled out an e

With regards to free bus boarding, Bus Captains are also unfamiliar with the Standard Operating Procedures such as disabling all entry EZ-Link readers instead of verbally telling commuters that the ride is free. Many commuters continue to tap their cards when boarding buses when free bus boarding is activated.

Despite all of SMRT’s RIMP shortcomings, its active deployment of Service Ambassadors (SAs) at station platforms is a welcome move to better assist commuters and reassure commuters during the CBTC testing period. It is also helpful to have more manpower on hand in the event of a rail disruption. In all, SMRT’s RIMP leaves much room for improvement and it is hoped that greater transparency and public outreach efforts can pacify commuters during this difficult implementation period.

Factfile

- All NSL + EWL trains are equipped with both legacy Westinghouse signalling system and new CBTC signalling system – but C151B trains (and all models after that) are only equipped with the CBTC signalling system

- All NSL + EWL tracks equipped with both legacy Westinghouse signalling system and new CBTC signalling system – but Tuas West Extension is CBTC equipped only

- Traction motors on trains:

- C151 (61 trains): 4-quadrant/GTO chopper control (Mitsubishi Electric) / 5 trains upgraded with IGBT-VVVF (Toshiba)

- C651 (19 trains): GTO–VVVF PWM (Siemens) / IGBT-VVVF (Toshiba) after refurbishment Refurbishment cancelled

- C751B (21 trains): IGBT-VVVF (Fuji Electric)

- C151A & C151B (80 trains) – IGBT-VVVF (Fuji Electric)

- 3 Forms of driving modes on all trains

- ATO: Automatic Train Operation

Also known as ‘Automatic Mode’, used during normal operating conditions (Both Westinghouse and CBTC). Under Westinghouse signalling, train operators only control door operations and setting the train in motion. Under CBTC, ATO mode covers most or all aspects of normal operation without the need for driver input. - CM: Coded Manual

Also known as Protected Manual mode. Under CM, trains are manually driven within the limits of the safe operation with all safeguards in place. Frequently used during wet weather under Westinghouse signalling. Can be identified by a steady orange/yellow light at the front of the train. - RM: Restricted Manual

Under RM, trains are driven on-sight without safeguards in place, but limited to a very slow speed (18kmh). Frequently used during shunting operations or to intentionally override faulty trackside signals. Can be identified with a flashing orange/yellow light at the front of the train.

- ATO: Automatic Train Operation

Summary

- CBTC implementation fell behind schedule from the start

- CBTC had to be implemented on the NSL before the Tuas West Extension could be opened, owing to limited number of trains

- C151B trains on the NSL allowed for older trains to be reallocated to the EWL

- Pace of implementation worked against LTA; faults occurred often on the NSL

- Signalling system is constantly being fine-tuned and is expected to stabilise several months after implementation

Case studies – London (Urban Metros)

Perhaps the most well-known rapid transit system in the world, the London Underground experienced many difficulties when it implemented moving-block signalling systems. All these systems utilise TBTC (Transmission Based Train Control) rather than radio-based CBTC owing to the reliability of track loops over radio communications. In this section, TBTC and CBTC are used interchangeably.

London Underground chose not to adopt radio-based CBTC in line with general CBTC advancement as the untested technology was deemed as too risky. The same technology is used by the Victoria Line, Jubilee Line, Northern Line, and other rapid transit systems including Vancouver’s SkyTrain, Toronto’s SRT, San Francisco’s Municipal Railway (MUNI) and Hong Kong’s MTR. Fast-forward several years, LTA had opted for the radio-based CBTC on likely because of the reliability it experienced with radio-based CBTC on the NEL, CCL and DTL.

The first CBTC-upgraded Underground line was the Jubilee Line, of which Thales supplied the signalling equipment (the Docklands Light Railway was upgraded to CBTC several years prior). Upgrading and testing work required the closure of sections of the Jubilee line each weekend during 2009. Although the project was due for completion in March 2010, the closures continued through 2010 and only finished in spring 2011. The programme of temporary closures for engineering work was criticised by many. Similar difficulties were encountered during the Victoria Line signalling upgrade, necessitating weekend closures before a phased introduction could take place. Many issues were encountered before the two lines finally achieved commissioning in 2011 and 2012, in time for the 2012 London Olympics.

With the lessons learnt, the CBTC upgrading of the Northern Line was much smoother despite the greater complexity of the line. Migration strategy centred staged implementation, and a six-month period of ‘shadow-running’ before live implementation of the system. To eliminate organisational issues, both teams from London Underground and Thales occupied the same premises in Canary Wharf, allowing engineers to work much more closely together for the successful implementation of the new signalling system.

London’s complicated Sub Surface Lines (comprising the Circle, District, Metropolitan and Hammersmith & City Lines) are also being resignalled by Thales. It was awarded a £760m contract to renew the signalling and train control systems by implementing a radio-based CBTC system, with the ‘main benefits’ to be delivered by Year 2022. The new contract replaces an older £345m contract awarded to Bombardier in June 2011 but terminated in December 2013, with the company unable to deliver a system suited for the complex nature of the network.

Case studies – Japan (Suburban railways)

In Japan, CBTC technology is not prevalent but a similar system, ATACS, has been developed by East Japan Railway Company (JR East) and entered live trials on an 18-kilometre stretch of the suburban Senseki line between Aoba-dori and Higashi-Shiogama, serving the city of Sendai.

ATACS stands for Advanced Train Administration and Communication System, and is a radio-based moving-block system that offers cab signalling with full train protection. It is primarily intended for suburban passenger networks and mixed-traffic railways which utilise a mix of rolling stock designs. The braking profile is then calculated for each type of train and its position, and also factors in the location and activation of railroad crossings.

Although the March 2011 Tohoku Earthquake damaged critical infrastructure, the ATACS system was repaired and introduced in October 2011. It has achieved stunning reliability figures – up till 2016, availability of 99.99999% was achieved, with a radio interruption caused a 10-second failure in one six-month period.

JR East is scheduled to roll out ATACS on the Tokyo suburban network with the 37-kilometre Saikyo Line between Ikebukuro and Omiya, scheduled for the autumn of 2017. It 2014, it also selected Thales to design and install a CBTC for the 30-kilometre Joban Line between Ayase and Toride, which would then allow JR East to compare ATACS with European CBTC (plans were cancelled in October 2017 due to project complexity and high capital investment leading to poor cost-effectiveness). JR East intends to equip ATACS on the Koumi Line by 2019 and the entire Tokyo metropolitan area by 2036.

Conclusion

The CBTC upgrade is an overdue and necessary major upgrade to boost capacity on our rail network and disruptions are an inevitable part of this transition. As SMRT, LTA and Thales engineers continue to iron out issues with the new signalling system, commuters are urged to be patient during the transition period and plan for additional travel time and alternative travel routes.

Along with additional trains purchased by LTA, commuters can expect shorter headways and smoother and less crowded journeys when the Thales CBTC signalling system is fully commissioned on the NSL and EWL.

This article has been written from the perspective of an industry outsider, and the content covered here is likely just the tip of the iceberg in regards to technical and policy details. With LTA and SMRT’s traditionally guarded stance against the disclosure of such details to the public, it remains difficult for the public to gain a better knowledge of the CBTC implementation process apart from the limited information contained in LTA’s official press releases.

Annexe: List of signalling faults attributed to the CBTC

- September 15, 9:06pm: “Signalling system fault”

Additional 20 minutes of travel time from Toa Payoh to Marina South Pier, free regular bus services at all affected stations. Train services resumed at 10:09pm. - August 18, 6.32am: “Signalling system fault” near Ang Mo Kio

Additional 45 minutes of travel time from Sembawang and Marina South Pier, revised to 30 minutes at 8:20am and 15 minutes at about 9:05am. Free regular bus services and free bridging bus services offered between Sembawang and Marina South Pier since the onset of disruption.

Attributed to a defective train transmitting erroneous signals to the Wayside Radio Units (WRUs) along the NSL, causing the WRUs to fail. As a result, trains had to move at slower speeds for safety reasons. - August 17, 6:18pm: ‘New signalling system fault’ at Ang Mo Kio

Additional 20 minutes of travel time from Yishun to Marina South Pier, increased to 25 minutes at 6:43pm at 40 minutes at 7:00pm. Free regular bus services between Marina South Pier and Ang Mo Kio since the onset of disruption, upgraded to free bridging bus services from 7:28pm. Revised to 15 minutes at 7:57pm and train services resumed at 8:18pm. - June 30, 6.32am: ‘Signal track fault’ at Ang Mo Kio

Additional 10 minutes of travel time from Woodlands to Ang Mo Kio, revised to 15 minutes at 7 am. Cleared at 8.50am. - June 28, 5:22pm: Signal fault across entire TWE sectors

Attributed to Thales engineers missing a step while loading a new radio software, causing a system error that disrupted radio communications between trains and lineside antennas, and all trains came to a halt as a safety feature

No train service between Joo Koon and Tuas Link, restored 45mins later - June 28, 5.15pm: Signal fault across entire NSL / TWE sectors

Additional 30 minutes of travel time across the entire line, later changed to no train service until further notice (5.37pm), partial followed by full restoration 2 hours later

Attributed to Thales engineers missing a step while loading a new radio software, causing a system error that disrupted radio communications between trains and lineside antennas, and all trains came to a halt as a safety feature - June 11, 6.10pm: ‘Signalling system fault’

Additional 20mins travelling time between Choa Chu Kang and Jurong East with free bus services activated. Restored at 6.50pm. - June 2, 5:05pm: Signalling system checks’

Additional 15mins travelling time due to ‘signalling checks’ could cause delays of up to 15 minutes, updated to additional 30mins travelling time between Yishun and Yew Tee with free bus boarding and bridging buses offered. Resumed at 8pm. - June 1, 6.47pm: ‘Signalling system fault’

Additional 20mins travel time between Jurong East and Marina South Pier, free bus services available between Jurong East – Choa Chu Kang and City Hall – Ang Mo Kio. Updatd to 15mins at 7:17 pm. Restored at 7:41pm, free bus services ceased. - May 29, 6pm: ‘Signalling fault’

Additional 20mins travelling time between Choa Chu Kang and Jurong East with free bus services activated. Restored at 6.25pm - May 28, ‘Signalling fault’

No train service between Marina Bay and Marina South Pier for around 3 hours, free regular bus services activated

This list only covers delays officially reported by SMRT.

Annexe: Timeline of CBTC events

- 2012: Signalling upgrade starts, projected commissioning in 2016

- 2015 (Dec): 91% and 41% of installation complete on the NSL and EWL respectively

- 2016 (Aug): Trial runs commence on the NSL during off-service hours

- 2016 (Oct): Launch of CBTC on the NSL delayed to 1Q 2017, 93% of testing complete on NSL, installation on EWL ‘more than 80% complete’

- 2016: Opening of Tuas West Extension delayed for more rigorous testing of the CBTC

- 2017 (Jan): NSL live testing announced for March 2017, ‘more than 85%’ installation complete on the EWL

- 2017 (28 Mar): CBTC live tested on the NSL for the first time, during the last hour of revenue service

- 2017 (16 Apr): Full-day CBTC testing on the NSL commences on Sundays

- 2017 (29 May): Daily full-day testing of the CBTC commences on the NSL

- 2017 (18 Jun): Opening of the EWL’s Tuas West Extension and partial CBTC implementation

- 2017 (15 Nov): Two trains collide at Joo Koon Station, injuring at least 29 people.

- 2017 (Jul): Trial runs commence on the EWL during off-service hours, EWL live testing announced for December 2017

- 2018 (03 Mar): CBTC concurrently tested on NSL and EWL for the first time, simulating regular operations

- 2018 (26 May): Last day of legacy signalling system; entire NSEWL transitions to CBTC the day after

- 2018 (28 May): Daily full-day testing of the CBTC on the EWL (akin to full implementation)

- 2018 (Jun): Projected completion of installation work on the EWL

- 2018 (??): Projected full commissioning on the NSL

Gallery:

Gallery (LTA):

Diagrams produced by the LTA, re-published by Mothership.

CBTC signalling equipment installed on trains:

- Radio and Antenna – For radio communication with lineside antennas

- Train Operator Display – Signalling system interface, Replaces older dials

- Speed sensor, transponder reader, proximity sensor, accelerometer – Used to calculate the position of the train in real time

CBTC signalling equipment installed on tracks (viaducts and tunnels):

- Radio and antenna – For radio communication with trains

- Fibre-optic cables – Links radio antennas to wayside controllers for two-way communication

- Transponder -For trains to determine their location on the track

- Proximity plate – Determines if trains have aligned correctly with platform

- Signals -Upgraded signals reflect new CBTC zoning

CBTC wayside signalling equipment:

- Relay Interlocking: Racks of electro-mechanical relays offer interlocking protection and is a key part of the legacy Westinghouse signalling system (Photo: LTA)

- Computer-based Interlocking: A signalling cabinet containing multiple modules, offering interlocking protection as part of the Thales CBTC signalling system (Photo: LTA)

Related Content:

- Communications Based Train Control (CBTC) – Land Transport Guru

- New CBTC Signalling System: 9 Things to Know – Land Transport Guru

- North South Line – Land Transport Guru

- East West Line – Land Transport Guru

- Tuas West Extension – Land Transport Guru

External Links & References:

- Improving the MRT – SMRT Blog

- Re-signalling of the North-South East-West Lines – SMRT Blog

- Re-signalling Update: Your Questions Answered Here – SMRT Blog

- 7 questions about SMRT Train’s new signalling system – SMRT Blog

- Fine-tuning the New Signalling System – SMRT Blog

- The Rail Report: Expansion and Upgrading of Rail Network on Schedule (Nov 2015) – LTA

- The Rail Report: New Signalling System, Rail Line and Extension and Trains Next Year (Oct 2016) – LTA

- The Rail Report: Higher Reliability and Expanded Network in 2017 (Jan 2017) – LTA

- The Rail Report: Rail Reliability Continues to Improve – More Rail Renewal Projects in the Pipeline (May 2017) – LTA

- Joint Media Release by the Land Transport Authority (LTA) & SMRT – New Signalling System Trial on North-South Line Begins on 28 March 2017 – LTA

- Factsheet by the Land Transport Authority (LTA) & SMRT: Full-day Sunday Trial of New Signalling System for North-South Line from 16 April 2017 – LTA

- Joint Release by the Land Transport Authority (LTA) & SMRT – Software Update on North-South Line’s New Signalling System from this Weekend – LTA

- Launch of upgraded signalling system on North-South MRT line delayed to Q1 2017 (Oct 2016) – Straits Times

- Communications Based Train Control – Rail Engineer UK

- LU Northern line goes CBTC – Rail Engineer UK

- London Underground Sub Surface Re-Signalling – Rail Engineer UK

- ATACS – The Japanese Level 3? – Rail Engineer UK

- Overview of the ATACS Radio Train Control System – JR East paper

- Japan Railway Journal Episode 1 – ATACS mention

- London Underground gets more automated – Railway technical

- SelTrac® CBTC (Brochure) – Thales Group (PDF)

- SelTrac® CBTC (Brochure) – Thales Group (PDF)

- Thales CBTC Solutions – Igor Silajev (PDF)

- My thoughts on the recent signaling fiasco (sic) – user ‘luacs1998’ – Reddit Singapore

- Driverless Railway Systems – A case study of Singapore MRT System – Yee Boon Cheow (LTA) (PDF)

- Signalling faults hit North-South line two days in a row (29 May 2017) – Straits Times

- MRT commuters hit by North-South Line delays during evening rush hour due to ‘new signalling system checks’ (1 June 2017) – Straits Times

- Disruptions to train service on North-South Line, parts of East-West Line due to signalling fault: SMRT (28 Jun 2017) – Today Online

- North-South Line signalling system to take up to 6 months to stabilise – CNA

- 首都圏のICT列車制御、JR東が海外方式導入を断念-国産「ATACS」推進 – 日刊工業新聞

Back to Train Articles

With thanks! Valuable information!

Nice article. But I think it is time to add the section of Train collision in Joo Koon yesterday due to CBTC.

Perhaps the day will come when new train cabins use the driverless design (C751A/C830/C951) and no longer have a dedicated driver cab partition. Passengers can then finally enjoy a track view of the EWL/NSL.

Thnx guys! Great article…from an engineering and neutral perspective.